Earth-Rite® II MGV

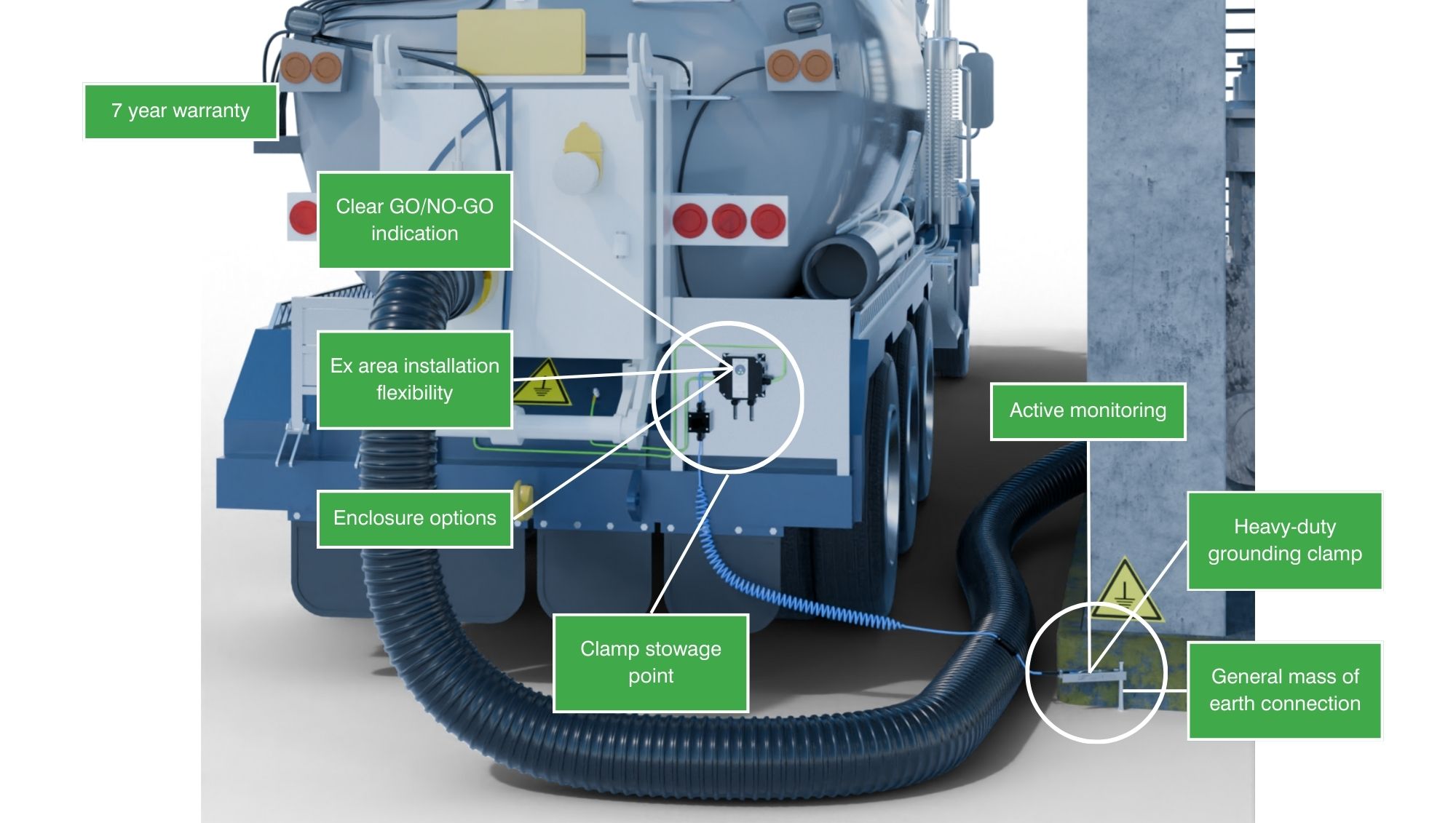

Newson Gale’s dedicated truck mounted static earthing system

Actively monitors the resistance of the circuit between the vacuum truck and the earthing point to 10 ohms or less.

DOES NOT require calibration at installation or throughout its lifecycle.

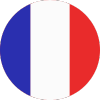

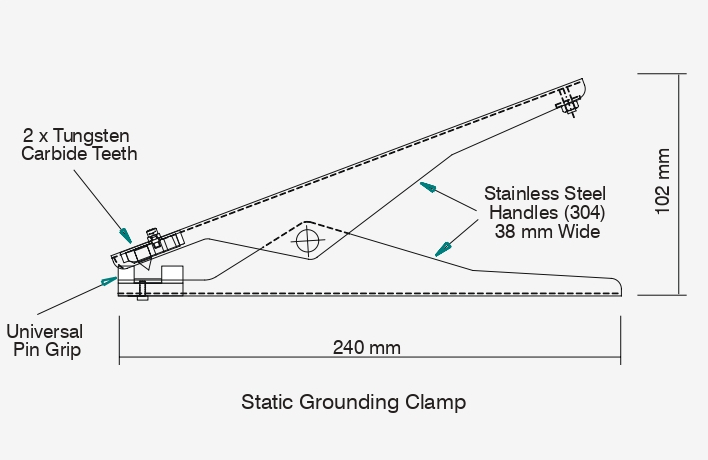

Utilises a heavy-duty stainless-steel clamp, that combines sharp tungsten carbide teeth with a strong torsion spring to establish, and maintain, a positive connection to the vacuum truck for the duration of the loading/unloading operation.

Grounding clamps DO NOT contain any insulating materials (rubber/plastic) that exceed the volume or surface area for Ex areas as specified in IEC TS 60079-32-1 (does not require rubber handle).

7 year warranty against manufacturer’s defects on PCBs.

1 year warranty on mechanical parts.

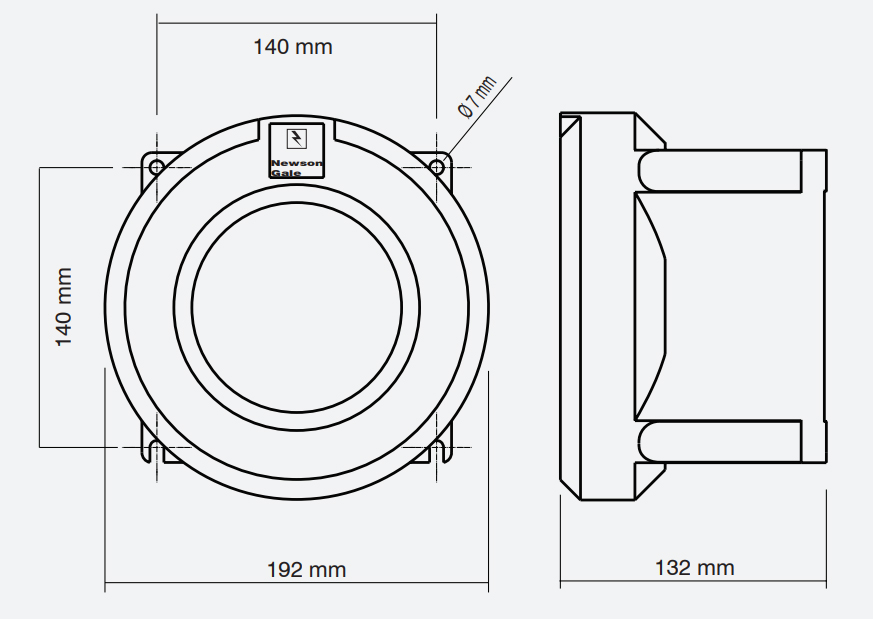

GRP Enclosure

Zone 2 Gas/Vapour Atmosphere – Zone 21 & 22 Dust Atmospheres

Power Supply & Monitoring-Unit

| Power Supply | 115 V or 230 V AC |

|---|---|

| Power Rating | 10 watt |

| Ambient Temperature Range | -40°C to +55°C |

| Ingress Protection | IP 66 |

| Weight | 2 kgs (4.4 lbs) nett |

| Construction | Carbon-loaded GRP |

| Monitoring Circuit | Intrinsically safe |

| Monitoring Loop Resistance | Nominally ≤10 Ohm (±10%) |

| Output Relay Contact Rating | 2 off voltage free change-over switch contacts 250 V AC 5 A 500 VA max resistive 30 V DC 2 A 60 W max resistive |

| Cable Entries | 7 x M20 (2 x plugged) |

Junction Box/Stowage Point

Grounding Clamp

| Clamp Design | 2 pole with tungsten carbide teeth |

|---|---|

| Body | Stainless steel (SS grade: 304) |

| ATEX: | Ex II 1 GD T6 (Assessed to EN 13463-1 : 2009) Sira 02ATEX9381 ATEX Notified Body: SIRA |

| FM: | Certificate of Compliance number: 3046346 |

| IECEx: | Ex h IIC T6 Ga Ex h IIIC T85°C Da Ta = -40°C to +60°C IECEx EXV 20.0033 IECEx Certified Body: ExVeritas |

| UKCA Ex: | Ex II 1 G Ex II 1 D Ex h IIC T6 Ga Ex h IIIC T85°C Da Ta = -40°C to +60°C ExVeritas 21UKEX0842 UKCA Ex Approved Body: ExVeritas |

Ex d Enclosure

Ex d (Zone 1 Gas/Vapour Installations – Zone 21 Dust Atmospheres)

Monitoring Unit

| Power Supply | 12 V or 24 V DC |

|---|---|

| Power Rating | 10 watt |

| Ambient Temperature Range | -40°C to +55°C |

| Ingress Protection | IP 66 |

| Weight | 4.5 kgs (9.9 lbs) nett |

| Construction | Copper-free cast aluminium |

| Monitoring Circuit | Intrinsically safe |

| Monitoring Loop Resistance | Nominally ≤10 Ohm (±10%) |

| Output Relay Contact Rating | 2 off voltage free changeover switch contacts 250 V AC 5 A 500 VA max resistive 30 V DC 2 A 60 W max resistive |

| Cable Entries | 7 x M20 (2 x plugged) |

Junction Box/Stowage Point

Grounding Clamp

| Clamp Design | 2 pole with tungsten carbide teeth |

|---|---|

| Body | Stainless steel (SS grade: 304) |

| ATEX: | Ex II 1 GD T6 (Assessed to EN 13463-1 : 2009) Sira 02ATEX9381 ATEX Notified Body: SIRA |

| FM: | Certificate of Compliance number: 3046346 |

| IECEx: | Ex h IIC T6 Ga Ex h IIIC T85°C Da Ta = -40°C to +60°C IECEx EXV 20.0033 IECEx Certified Body: ExVeritas |

| UKCA Ex: | Ex II 1 G Ex II 1 D Ex h IIC T6 Ga Ex h IIIC T85°C Da Ta = -40°C to +60°C ExVeritas 21UKEX0842 UKCA Ex Approved Body: ExVeritas |

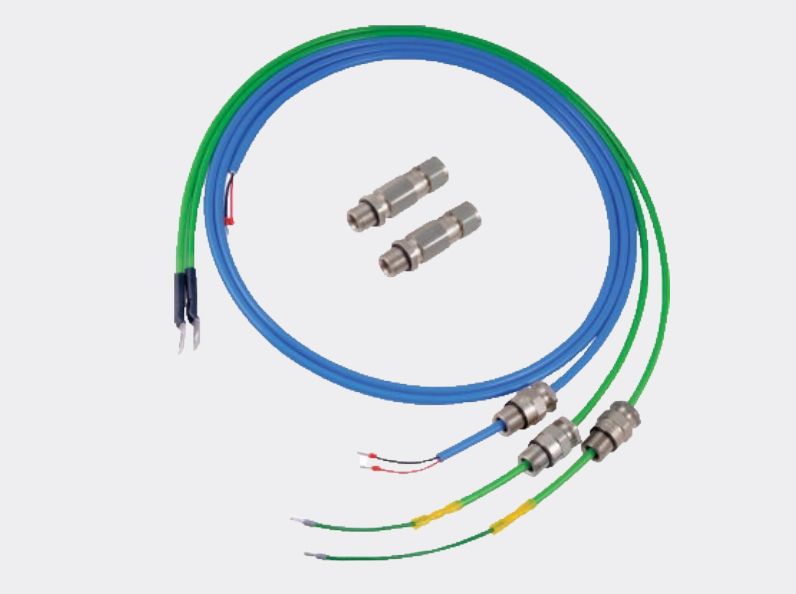

Spiral Cable

| Cable | Blue Cen-StatTM Hytrel® sheath (Static dissipative, chemical & abrasion resistant) |

|---|---|

| Conductors | 2 x 1.00 mm² copper |

| Length | 15 m extended (optional cable reel and additional lengths of Hytrel® cable available – please enquire) |

Overview of the Earth-Rite® MGV

The Earth-Rite® MGV is a truck mounted static earthing system that provides road and vacuum tanker operators, HAZMAT teams and bulk distributors with a means of connecting their trucks to earth to mitigate the effect of electrostatic charge generation caused by the transfer of materials in Ex atmospheres. The transfer of flammable materials into and out of road tankers normally takes place at dedicated road tanker loading gantries where static earthing systems are installed at the gantry. However, the transfer of flammable materials can take place in less controlled circumstances.

For example, vacuum tankers can be used in scenarios ranging from storage tank cleaning to the recovery of spills at multiple locations around refineries and large chemical manufacturing complexes. To have static earthing systems installed at every location on large sites where vacuum truck operations are carried out would most likely be cost-prohibitive. Bulk distributors may have to deliver products to locations where effective static earthing measures are not in place. HAZMAT teams may need to recover flammable material resulting from bulk road tanker spills in a variety of locations where static earthing opportunities are limited. For mobile earthing applications, many fleet operators utilise basic clamps and cable reels, however, basic methods like this cannot test the earthing point to assess if it has a connection to the general mass of the earth nor can they monitor the tanker’s connection to the earthing point for the duration of the material transfer operation.

Some sites, like refineries and large chemical manufacturing complexes, will only permit transfers to take place after one of their competent electrical persons (CEP) has carried out a resistance meter test between the designated earthing point local to the transfer operation and the tanker. Some drawbacks of this method are:

- The vacuum truck team can be waiting for long time periods until a CEP is available to perform resistance reading checks.

- The tanker’s earth connection cannot be monitored for the duration of the transfer operation as the vacuum tanker team are engaged in tasks to transfer the material.

Having a truck mounted static earthing system that possesses the same capability as earthing systems typically used at loading gantries provides a higher level of flexibility. At the same time, it enhances the method of verifying and monitoring the connection to the earthing point when compared with basic clamps and cable reels and enhances the safety to plant and personnel.

It should be noted that all metal parts should be bonded together. This ensures that electrostatic charge cannot accumulate on isolated components (e.g., cabinets, man lid covers, etc.) when earthing by the Earth-Rite® MGV.

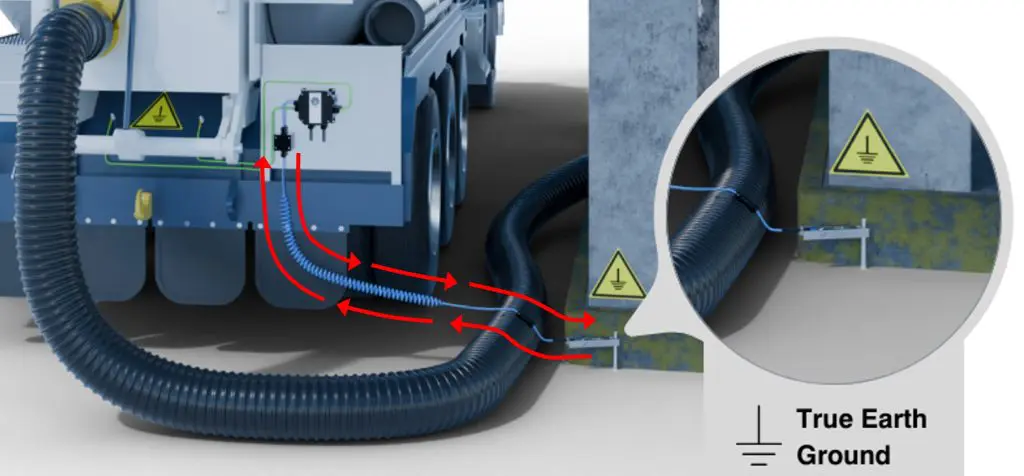

Operation

In line with recommended practice, it is advisable that drivers and operators follow a simple protocol of “Clamp on First, Clamp off Last” (CoF/CoL). This should, wherever possible, be incorporated into the driver or process operator’s standard operating procedure (SOP).

The Earth-Rite® MGV utilises a simple-to-follow “GO/NO-GO” user interface. The primary indication of a connection to earth is provided by a traffic light system of red and green LED indicators. From the driver’s perspective, the primary action is to take the earthing clamp attached to the system, ensure the red LED is on and green LEDs are off, and then connect the earthing clamp to an earthing point.

There are no other operating interfaces, e.g., switches, dials, or resistance meter readings, required for the driver to engage with. They simply connect the clamp to an earthing point and the Earth-Rite® MGV will confirm if a healthy earth is present.

If the operating parameters described in the next section are achieved, the green LED cluster flashes continuously to indicate to the driver that the truck is earthed. The driver can then proceed to the next step in the material transfer operation.

The earthing clamp should never be removed during the material transfer operation. Detaching the clamp from the earthing point should be the very last step of the process.

Drivers/Operators need to be aware of this simple CoF/CoL procedure before carrying out product transfers.

Operating parameters

To determine if the truck has a good earth connection, the system directs a signal into the earthing point to be tested, via the Earth-Rite® MGV’s earthing clamp.

Earthing points encompass:

If the resistance of the earthing point to earth is approximately ≤ 1000 ohms, the system then switches to monitoring the resistance of the connection between the truck and the earthing point to verify the monitored resistance is ≤ 10 ohms for the duration of the transfer operation.

Using two resistance threshold values may at first appear to be a little confusing, but there is a logical explanation as to why Newson Gale uses these parameters.

Whilst it is well cited that a connection of ≤ 1 megaohm to the general mass of the earth is adequate for static dissipation, it is not recommended to use a value this high in Ex atmospheres. Various guidance documents (IEC 60079-32-1, NFPA 77, etc.) state recommended maximum resistance thresholds for different scenarios.

The threshold resistance of ≤ 1000 ohms is advised in NFPA 77 “Recommended Practice on Static Electricity”*. This publication cites that HAZMAT teams engaged in material recovery operations, like road tanker fuel and chemical spills, may need to install temporary earth rods in soil or earth local to the recovery operation. Testing of the resistance to the general mass of the earth is a one-time check as there should be no disturbance to permanently installed earth electrodes or temporary electrodes buried in soil during the material transfer operation.

The next step is to monitor the connection between the Earth-Rite® MVG’s connection to the truck and the verified earthing point. The purpose of this function is to determine if there is a low resistance path between the truck and the verified earthing point for the duration of the material transfer operation.

The resistance monitoring threshold of ≤ 10 ohms is selected from a wide range of industry guidance for controlling static electricity in Ex operations. Independent bodies like the International Electrotechnical Commission (IEC), CENELEC (CEN), and National Fire Protection Association (NFPA) recommend resistance levels of 10 ohms or less between the object requiring static earthing and the verified earthing point.

The reason for this is that a resistance higher than 10 ohms in the circuit between the object, in this case the truck, and the verified earthing point, indicates potential compromise of the earthing circuit, like a poor initial connection to the earthing point via the earthing clamp, or loose/corroding connections that could otherwise prevent the passage of static charges to earth.

In the vast majority of applications, the object requiring static earthing will be made of metal, as will the verified connections to earth. Given that the static charge is dissipating from the truck through metal connections from the tanker to the tungsten carbide teeth on the earthing clamp, 10 ohms or less is an appropriate benchmark.

It is important to emphasise that the Earth-Rite® MGV is the point of contact between the tanker and the earthing point, where any static charge will be dissipated.

When both input parameters (≤1000 ohms and ≤10 ohms) are met, the Earth-Rite® MGV’s LED indicators switch from solid red to flashing green. The indicators continue to flash for the duration of the time the clamp is connected to the earthing point. When the system goes permissive, a pair of NO/NC volt-free contacts changes state.

IEC 60079-32-1 “Explosive Atmospheres Part 32-1 Electrostatic Hazards – Guidance”.

8.8.4 Vacuum trucks

“Vacuum trucks should be connected to a designated site earth before commencing any operations. In areas where site earths are not present, i.e., where portable earthing rods are required, or there is doubt regarding the quality of site earths, the resistance to earth should be verified prior to any operation. When the truck is connected to a verified earth, the connection resistance between the truck and verified earth should not exceed 10 Ω for pure metallic connections or 1 MΩ for all other connections.”

13.2.2 Practical criteria

“Although a value of up to 1 MΩ is acceptable for static dissipation, values above 10 Ω may give an early indication of developing problems (e.g. corrosion or a loose connection) and should be investigated. It is important that all connections are reliable, permanent and not subject to deterioration”.

*NFPA 77 2024 “Recommended Practice on Static Electricity”

7.3.1.6.1.1

“In field-based situations such as HAZMAT response operations or flammable/combustible material spill control and transfer, it might be necessary to establish a temporary or emergency grounding system in a remote location in order to dissipate electrostatic charges. In such situations, various types of conductive grounding electrodes can be used, such as rods, plates, and wires, which are sometimes used in combination to increase surface area contact with the earth. If the purpose of the temporary grounding system is to dissipate static electricity, a total resistance of up to 1 Kiloohm (1000 ohms) in the ground path to earth is considered adequate. This can be measured using standard ground resistance testing instruments and is realistically and quickly achievable in most types of terrain and weather conditions.”

Intrinsically safe (IS) circuits

Because the truck is engaged in the transfer of hazardous materials in Ex atmospheres, the system utilises an intrinsically safe signal with the highest level of protection ‘ia’.

The benefit associated with this feature is that the energy in the electrical circuit that verifies and monitors the resistance of the earthing point will not exceed levels that have the potential to ignite all classifications of gases, vapours, and dust.

This is particularly relevant for scenarios where containment of gases, vapours, and dusts may be difficult to enforce due to the complexity of some operations (e.g., tank cleaning, spill recovery). At a minimum, any electrical equipment used in classified Ex atmospheres must carry the appropriate level of Ex system certification.

Output contacts

A pair of volt-free NO/NC contacts, and an optional single intrinsically safe output contact, can be selected for controlling equipment like pumps or valves to prevent material transfers from taking place if the tanker is not earthing. Additional equipment, like strobe lights, can also be interlocked with the Earth-Rite® MGV, especially for scenarios where the drivers/operators may need a secondary method of indication, as their view of the primary indicators on the MGV may be obstructed during material transfer operations.

Please note that in an emergency shutdown scenario, e.g., the connection to the earth has been compromised during the material transfer procedure, the product may continue to flow into or out of the tanker once the transfer process has begun. This could lead to the accumulation of static electricity on the tanker or objects connected to the tanker, e.g., hoses.

If a HAZOP assessment highlights the potential for such a scenario to occur, additional measures may need to be put in place. For example, it may be possible to determine the charge relaxation time of the material and issue an SOP to operators so that they do not approach the tanker or hoses during the specified time period. Site operators should retain the services of a static control consultant if this scenario could arise.

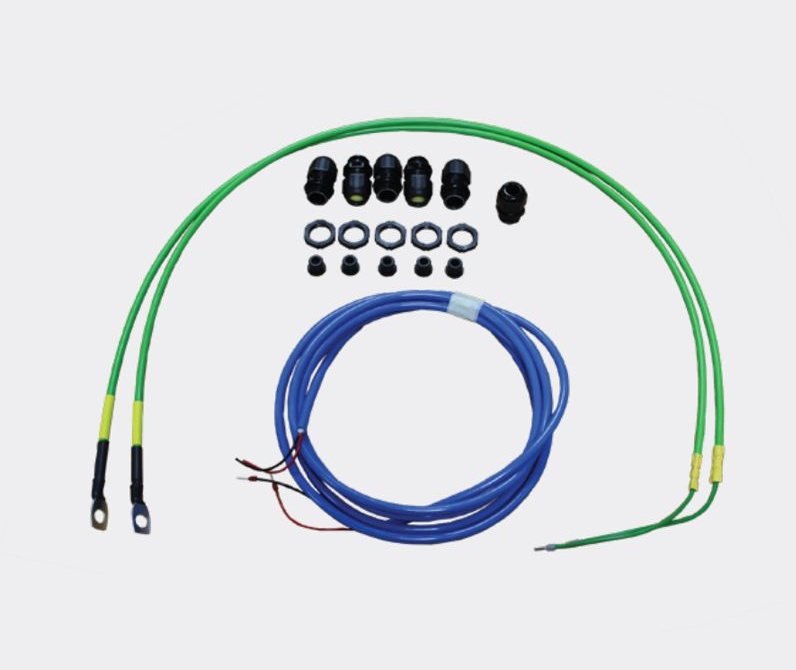

Installation

The Earth-Rite® MGV is simple to install and operate. Unlike many other static earthing systems, the Earth-Rite® MGV is designed to operate “out of the box”. It does not require any calibration at the point of installation nor throughout its time in use. Because the road tanker is electrically isolated from the earth by its tyres, it has a capacitance relative to earth. A simplified model of road tanker capacitance is the parallel plate capacitor, and road tankers are generally thought to have a capacitance value of greater than 1000 pico-farads (pF).

Newson Gale’s own research into road tanker capacitance shows high variations of capacitance depending on several variables. It is for this reason that the Earth-Rite® MGV, via its patented method of operation, can cater for such variables, thus eliminating the need to calibrate the system at the point of installation, or throughout its period in use.

Testers can be purchased with the system to ensure it is operating within the required design parameters highlighted above (see Operating parameters section). It should be noted that the system must be installed in accordance with the accompanying Instruction Manual, as failure to do so will invalidate the Ex hazardous area certificate of the system.

An installation kit consisting of glands and cabling specific to the enclosure selected and the zone location can be specified with the system.

The Earth-Rite® MGV is powered by the tanker’s 24v/12v DC battery. Please note that an Ex-competent person is required to carry out the installation of Ex-certified products, as per the product manual. If you have any doubts with respect to the installation requirements of Newson Gale equipment in Ex atmospheres, one of our CompEx certified engineers will be happy to support you.

- Gain insights into the specification of hazardous area certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of Ex equipment.

- Evaluate competency requirements for individuals.

- Navigate Ex equipment documentations.

UKCA Certificates - United Kingdom

ATEX Certificates - Europe

IECEx Certificates - International

cCSAus Certificates - United States

CCC Certificates - China

KCs Certificates - South Korea

P1 = one GRP enclosure

Book a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of hazardous area classifications at your location. The most effective way to identify what is applicable for your operations is by talking to our team. They will provide in-depth information on the products, features and how the range of options can be tailored to your needs.