Drum filling and the ignition risks of static electricity

Drum Filling: Static Electricity Ignition Risks

Protecting workers and company assets from ignitions caused by static electricity can’t be left to chance. In facilities where flammable and combustible products are processed, there’s a very high probability that static electricity is generated by the movement and agitation of vapours, liquids, and solids.

In filling operations, thousands of drums of flammable liquids are filled worldwide every week, and filling procedures vary from facility to facility. The risk of a fire or explosion caused by a discharge of static electricity in an Ex area is just too significant to ignore. However, despite the risks, good housekeeping, strict maintenance practices, and ignition risk identification, underpinned by static control mitigation measures, can ensure a safe working environment.

In industrial environments where there can potentially be flammable and combustible atmospheres, there are many metallic isolated conductors that, if not suitably earthed, can become electrostatically charged to a hazardous level.

Isolated conductors are likely sources of static ignition incidents in industry, ranging from small-scale fires through to major explosion damage and injury to facilities and personnel.

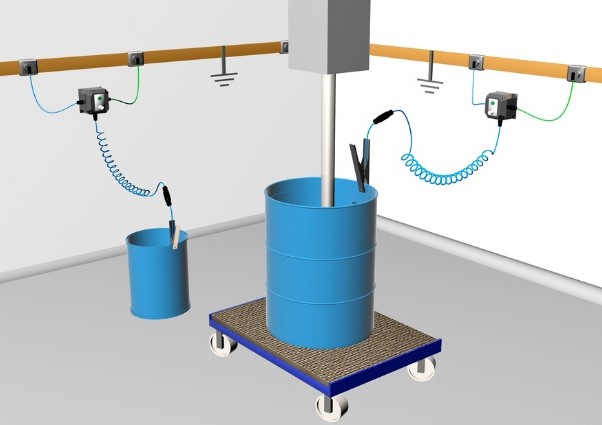

Mobile items of plant equipment, such as drums and trolleys, cannot be permanently connected to earth through the main plant structure due to the need to be transportable as part of the process operation.

That said, it is an absolute minimum requirement that each vessel should be earthed whenever a flammable mixture could be present, and those responsible for introducing control measures should be proactive in their approach.

Repeatability and risk

In industry, batch processes can require many hundreds or even thousands of earth connections to be made and broken every day; it is essential that good earth contact is made each and every time.

The effectiveness, reliability, and durability of any earthing clamp, system, and associated cabling are therefore key to keeping process operations safe from the dangers of a static discharge.

The speed and scale of modern manufacturing processes, coupled with changes to the nature and properties of many raw materials, have increased the range and number of applications where electrostatic charge can accumulate.

Drum filling operations require the repeated filling of drums on a continuous basis. Drums can be filled with:

- Fixed pumps that simultaneously fill four drums on a pallet.

- Fixed pumps on a rolling conveyor system.

- Portable pumps in a manual process operation.

As operations are typically carried out indoors, hazardous areas ranging from Zone 0 right through to non-hazardous safe areas can reflect a matrix of installation options and required layers of control that provide the best fit for the earthing applications.

Different zoning requirements coupled with the characteristics of the operation and scale of the hazard, particularly the amount of flammable or combustible material at risk of ignition, can influence the kind of solution specified.

| Incident Type | Incident Number | Facility | Date | Location | Causalities |

| Explosion | 1 | Large Storage Tank | 1953 | Germany | 29 Fatalities |

| Explosion | 2 | Large Storage Tank | 1954 | The Netherlands | – |

| Explosion | 1 | Loading Tanker | 1956 | USA | – |

| Explosion | 1 | Tanker | 1966 | USA | – |

| Explosion | 3 | Crude Oil Tankers | 1969 | The Netherlands | 5 Fatalities and 100 Injuries |

| Fire and Explosion | 303 | Filling of Containers (storage tanks, road, rail tanks and drums) | 1979-1988 | UK | – |

| Fire | 243 | Petrol Stations | 1993-2004 | Around the World | – |

Static inhibitors in industrial processes

Items such as drums and containers can have their conductivity affected by paints, coatings, or a buildup of product deposits.

These static inhibitors can be thick enough to keep electrostatic charges from dissipating altogether and can impede the integrity of earthing clamp connections. The solution is to use an earthing system with clamps that can pierce paint for a good metal-on-metal, low-resistance connection.

By providing a high-intensity flashing green LED when a positive connection to earth has been made, the Bond-Rite® range monitors the path to earth as well as reassuring the operator throughout the duration of the operation.

Passive earthing versus active monitoring with the Bond-Rite® range

In a typical drum filling operation, the standard approach of static earthing protection will be to earth the drum with a basic clamp and cable. Electrical isolators, such as those inhibitors listed above, prevent the clamp teeth from making a solid, reliable connection to the drum. Following repeated opening and closing cycles, clamp springs can stiffen, losing their capability, thereby reducing their capacity to make a reliable connection to equipment.

A Bond-Rite® CLAMP or Bond-Rite® REMOTE can provide workers with a visually verified earth connection to the site’s earthing network. Once the operators have attached the clamp, the high-intensity flashing green LED confirms a low-resistance connection to the drum. As long as the green LED is flashing, the operator can work safely in the knowledge that the Bond-Rite® will continuously monitor the circuit, ensuring static charge generated by the operation is transferred away from the potentially explosive atmosphere.

Imagine a scenario where up to 10 drums can be filled with portable pumps at a dedicated solvent filling location at any one time. Due to the pumps being held by the operators, they must continuously visually check the liquid level in the drum.

When management risk assess and analyses between interlocking the pumps with that of a manual shutdown by the operator, they deem it sufficient for the operator to both start and stop the pump in response to visual indication of each drum’s earth connection.

A solution like the Bond-Rite® REMOTE EP can be specified to combine each circuit monitoring with visual indication, providing an additional layer of protection when monitoring multiple drums off a single power supply on a 24/7 basis.

The benefit of this type of solution is that it closes the gap between no visual indication via “passive” earthing clamps and “off-the-shelf” earthing solutions with interlocks that require a mains line supply, or a DC supply delivered to 10 separate earthing systems operating in the hazardous area.

A solution like the Bond-Rite® REMOTE EP, which only requires a single 230 v AC feed to its Zone 2/21 mounted power supply, can deliver Intrinsically Safe (IS) power to 10 earth status indicators suitable for Zone 20/21, which can then independently monitor the earthing status of each individual drum.

If filling is carried out on a less routine basis, installation time can be reduced by specifying earth status indicators that are powered by their own internal battery.

For somebody tasked with controlling static ignition hazards, solutions tend to fall between basic clamps and cables and static earthing systems. A basic clamp and cable provides a low level of scrutiny when dissipating static, but as an introductory level of protection is sufficient and must be considered a fundamental requirement.

Static earthing systems offer the most layers of control and protection over static ignition risks, particularly as they can monitor the integrity of the connection to the process equipment, provide a visual indication to operators of a positive, low-resistance, earth connection (Bond-Rite® range), and shut down the process if the earthing is compromised (Earth-Rite® range only).

The benefit for product specifiers and buyers, particularly for processes that cannot be interlocked, is that they can enhance the controls over their static ignition hazards to a much higher level than basic clamps without having to stretch their budget to the more established interlockable static earthing systems.

Passive monitoring

- A metallic earthing clamp designed to provide a resistance of 10 ohms or less.

- If there is a ‘break’ in the connection or the resistance to earth rises above 10 ohms, there is no way of knowing during the operation.

- Unable to confirm a good earth connection before the process begins.

IEC TS 60079-32-1,13.3.1.4 “Movable metal items” states:

“Portable conductive items (e.g. trolleys equipped with conductive rollers, metal buckets etc.) are earthed through their contact with dissipative or conductive floors.

However, in the presence of contaminants like dirt, or paint on the contact surface of either the floor or the object the leakage resistance to earth may increase to an unacceptable value resulting in possible hazardous electrostatic charge on the object. Where such situations are expected, the object should be earthed by an alternative means (e.g. earthing cable). A connection resistance of 10 Ω between the cable and the item to be earthed is recommended.”

NFPA 77, 7.3.1.6.1 “Bonding and Grounding” states:

“Where the bonding/grounding system is all metal, resistance in continuous ground paths is measured to verify mechanical integrity. (See A.3.3.2) Such systems include those having multiple components. Greater resistance usually indicates that the metal path is not continuous, usually because of loose connections or corrosion. A permanent or fixed grounding system that is acceptable for power circuits or for lightning protection is more than adequate for a static electricity grounding system. Static grounds should be made to the building steel, if possible. Grounding to power grounds or lightning protection systems is not recommended.”

A.3.3.2 Bonding

“A resistance not exceeding 10 ohms for copper wire or 25 ohms for stainless steel or other metals is typically found in practice. Higher resistances could indicate a lack of mechanical integrity.”

Note: Always check for and read the latest version of the International Standards Guidance and/or Recommended Practices.

Active monitoring

- Provides a resistance of 10 ohms or less as indicated via a high intensity flashing green LED within the system enclosure or on the Bond-Rite® CLAMP.

- The green (GO) indication aids the SOP, e.g., do not proceed until the LED has gone green.

- Operators and plant personnel are accountable and secure about their working environment. Provides confidence that the process is reliably earthed before the operation commences.

- Performance is continuously monitored throughout the duration of the operation.

Self-testing clamps with visual indication and monitoring

The Bond-Rite® range from Newson Gale provides enhanced safety and security by continuously testing the connection of the clamp to the drum or other metallic items of plant equipment in a complete loop made via the designated earthing point.

Designed for process areas where interlocking (automatic shutdown) is not possible/or required, operation is manual and monitored by an operator’s presence, or where the process times are not permanent.

These systems are designed around processing hazards where the responsibility is placed on the operator to provide the earthing process. Such restrictions do not mean that specifiers must take a downward leap to passive earthing clamps (non-monitored).

An intermediate layer of static earthing control is possible by installing Bond-Rite® solutions that can continuously monitor and verify that the resistance between the equipment to be earthed and a true earth ground source is 10 ohms or less.

Summary

To mitigate electrostatic discharges igniting combustible and flammable atmospheres, companies should risk assess their processes and equipment to ensure any potential sources of ignition are identified and managed correctly.

Incendive electrostatic sparks usually result from the lack of a thorough and detailed risk assessment, unintended changes to equipment during routine maintenance, and unsafe operator working practices. All potential sources of internal and external static discharges from process equipment situated in zoned and classified areas must be accounted for and managed in the appropriate way.

The primary mindset should be to source an earthing solution that provides the best level of protection and is capable of being incorporated alongside current operations. The more layers of control deployed to protect against an ignition source, the more likely static will be controlled in a safe, repeatable, and reliable way, day in and day out.

Naturally, the most desirable method of control is the prevention of charge accumulation; however, it is rarely attainable without additional consideration. The solution lies in preventing the charge from accumulating to unsafe levels where a discharge is likely to occur.

The object of static control measures is to provide a means by which charge can safely dissipate to the earth. The most secure means of preventing charge accumulation is to provide a reliable path to verified earth via earthing and bonding methods. It is fundamentally critical to take necessary precautions to prevent discharges that are powerful enough to cause ignition in a flammable or combustible atmosphere.

To help control these risks, Newson Gale offers a wide range of static earthing and bonding equipment, which is made to provide optimum safety in explosive atmospheres for a variety of process applications.

The Newson Gale range mitigates static charge accumulation by using practical and innovative design and ensures effective static control on three levels: earthing and bonding clamps, visual verification systems, and interlockable control systems.