Level of Control: Static Bonding and Earthing

The primary function of our static bonding and earthing products is to provide a reliable path for static charge to be transferred from the equipment at risk of static charge accumulation to the general mass of the earth. The transfer of electrostatic charge to the general mass of the earth limits the potential of the object to develop a voltage capable of discharging an incendive electrostatic spark.

In a busy working environment, it is beneficial if operators have an established SOP they can follow so they know when earthing of the process equipment at risk of charge accumulation has been established, and the next step in the process can commence. This is of particular significance if the object(s)* at risk of charge accumulation are mobile and require temporary earthing connections. A basic standard operating procedure of “Clamp On First, Clamp Off Last” should be followed wherever practical at all times.

* “object(s)” means any item of plant equipment that could be susceptible to electrostatic charging (e.g., drums, EX IBCs, road tankers, railcars, hoses, etc.)

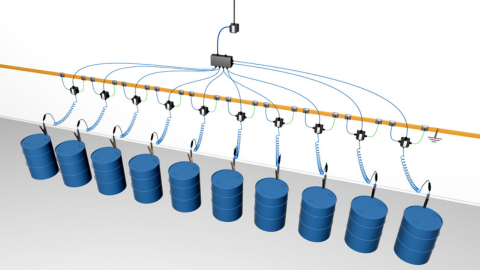

Regarding the “level of control” desired with respect to controlling the accumulation of static electricity a good place to begin is by providing operators with a visual reference that confirms when the object at risk of charge accumulation is connected to earth.

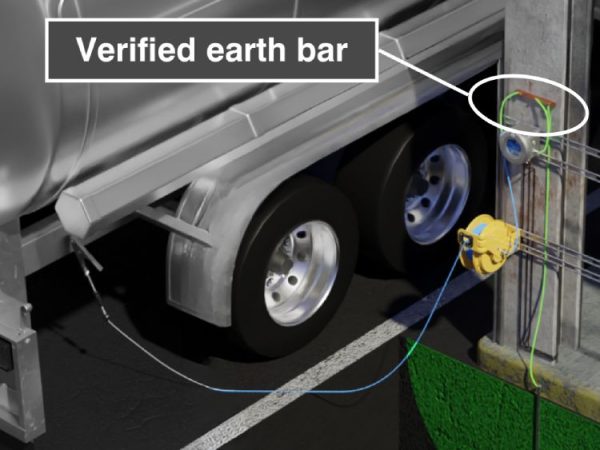

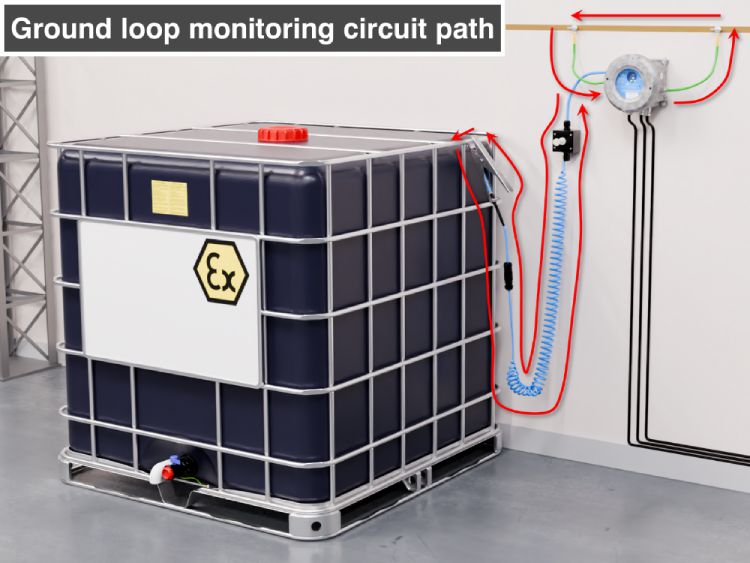

A visual reference, like a green flashing LED, informs operators that the connection to the verified earth bar has been established and that it is OK to proceed to the next step of the material processing operation. The primary input that determines if the object has been earthed is the electrical resistance present between the object to be earthed and the verified earth connection. The earthing solution actively monitors the electrical resistance in the circuit between the object requiring static earthing and the plant’s verified connection to earth for the duration of the material handling process.

When specifying earthing and bonding solutions, it is important to remember who the primary interface is being designed for and used by. Operators should not be expected to work with indication methods that have multiple status settings or be expected to interpret real-time resistance readings. Newson Gale advocates a simple and effective way of informing operators that an earth connection has been achieved, either through a clear red/green “traffic light” format or a clear flashing green LED indication. Also, take a look at our products used for static earthing of portable containers.

The earthing solution’s connection to the verified earthing bar is paramount to the safety of the system. Depending on the design of the intrinsically safe monitoring circuit, the connection will need either a high-integrity earth connection or a local verified earth connection. Utilising the design concept of galvanic isolation for the intrinsically safe circuit allows for the system to be installed to a local verified earth bar, often offering easier installation due to not having to install long cable lengths to a high-integrity earth.

The connection to the verified earth bar should also be actively monitored to ensure the electrical resistance present between the object to be earthed and the verified earth connection provides a passage for static charges to earth. Having an earthing system that incorporates two connections to the verified earth bar allows the earthing system to continuously monitor the circuit through the earth bar during the process.

Should a rise in resistance over the earthing system’s maximum resistance parameter occur in these connections, either through loose connections or degradation over time, then the earthing system will not go permissive. This provides maintenance staff with an opportunity to investigate and identify the source of resistance (e.g. loose or broken connections) and rectify it to maintain the safety of the process.

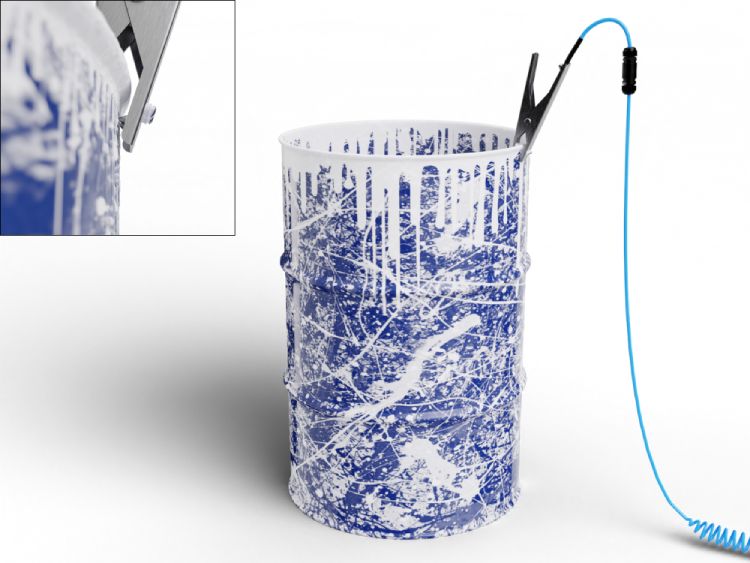

The primary source of electrical resistance in many applications will be the connection of the earthing clamp (or other connection method) to the object requiring static earthing. The operations of many industrial processes will very often result in equipment being covered in product deposits, thick protective coatings, rust or the build-up of dirt/grime over a sustained time period.

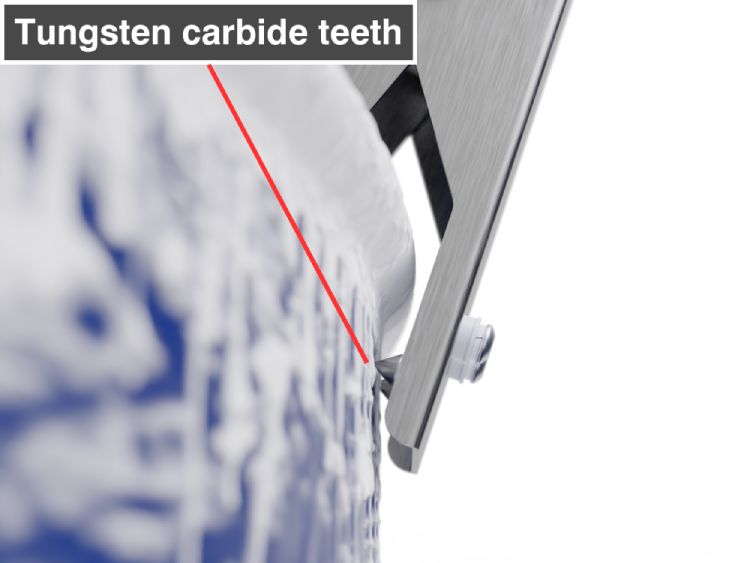

In order to achieve a 10 ohms or less connection it is crucial that the earthing clamp is capable of penetrating such layers in a repeatable, robust and reliable way. It is for this reason that Newson Gale pioneered the use of the hard-wearing metal tungsten carbide (table) to produce teeth capable of penetrating connection inhibitors like product deposits, paint coatings, rusted surfaces, etc.

The sharpened profile of the teeth used in combination with a strong spring housed in a heavy-duty stainless steel body enables their repeated use in harsh industrial environments. Not only are strong initial connections made to the equipment, but they are also maintained for the duration of the material handling process.

Although the magnitude of electrical current generated by electrostatic charging can be relatively small, normally in the micro-amp range, the resulting voltages can be very high and well beyond the breakdown voltage of air. It is commonly quoted that a theoretical resistance of 1 meg-ohm to true earth will dissipate static electricity. However, due to the harsh industrial environments in which earthing equipment typically operates, and because most earthing applications require many repeated connections and disconnections to process equipment, the robustness and reliability of the earthing solution are the primary concern with respect to intended performance.

For that reason, independent bodies like the International Electrotechnical Commission (IEC) and National Fire Protection Association (NFPA) recommend resistance levels of 10 ohms or less between the object requiring static earthing and the verified earthing point. The reason for this is that resistances higher than 10 ohms in the circuit between the object and the verified earthing point indicate potential compromise of the earthing circuit, like a poor initial connection to the equipment via the earthing clamp, or loose/corroding connections that could otherwise prevent the passage of static charges to earth.

In addition to the publications highlighted above, an electrical resistance of 10 ohms has often been cited in industry specific guidelines and scientific journals as a good benchmark for indicating a reliable path to a verified earthing point. In the vast majority of application settings, the object requiring static earthing will be made of metal, as will the verified connections to earth.

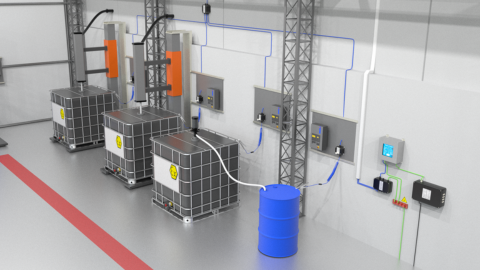

In addition to visual indication and active monitoring of the earthing circuit, an added level of active control is to interlock the earthing system with the process control circuits. This provides the added benefit of preventing the operation from the beginning if the earthing system does not provide a permissive signal to the PLC/control circuit, thereby preventing the generation and accumulation of static charge†.

This is particularly beneficial for operations where large quantities of material are being processed (e.g., 250l containers, 1000l EX IBCs, up to road tankers and railcars) as the systems controlling the movement of product could be controlled by PLCs and/or emergency shutdown systems.

The methods outlined above are “active” solutions. They provide a level of indication, monitoring and control that informs the site operator as to whether an earth connection has been established and is being maintained, for the duration of a material processing operation.

As the earthing systems have active electronics, they all require 3rd party certification (e.g. ATEX, IECEx, UKCA) for installation in potentially explosive atmospheres (a.k.a. EX atmospheres). It is therefore important for specifiers, designers, and installers to determine the hazardous area classification of the location where the active earthing system will be installed/operated to enable the selection of earthing systems that carry the appropriate hazardous area certificates.

† assumes the system is installed in accordance with the Instruction Manual, and the output contacts are used to prevent system startup and/or an emergency shutdown function.

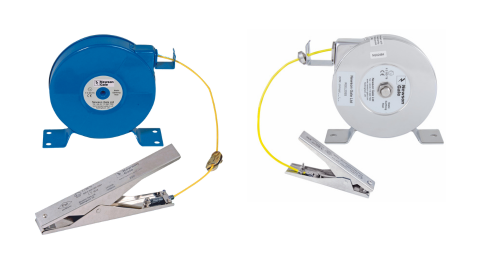

At the lower end of the scale is the option of specifying combinations of earthing clamps with cables or reels that provide none of the benefits listed above. In this case, we are describing “passive” earthing solutions where it is assumed that the connection between the object and the verified earthing point is performing the intended function of transmitting electrostatic charge to earth.

To compensate for the information gap provided to operators it would be prudent for competent electrical persons to test the electrical resistance of the connection of these installations with ohm meters (certified for use in EX atmospheres) on a regular basis to determine if there are breaks in electrical continuity that could otherwise impede the transfer of static charge to earth.

Additional certifications, (like FM approval), can provide a higher degree of confidence in the ability of the clamp to establish and maintain a secure connection to equipment but it will not completely compensate for the benefits provided by active solutions.