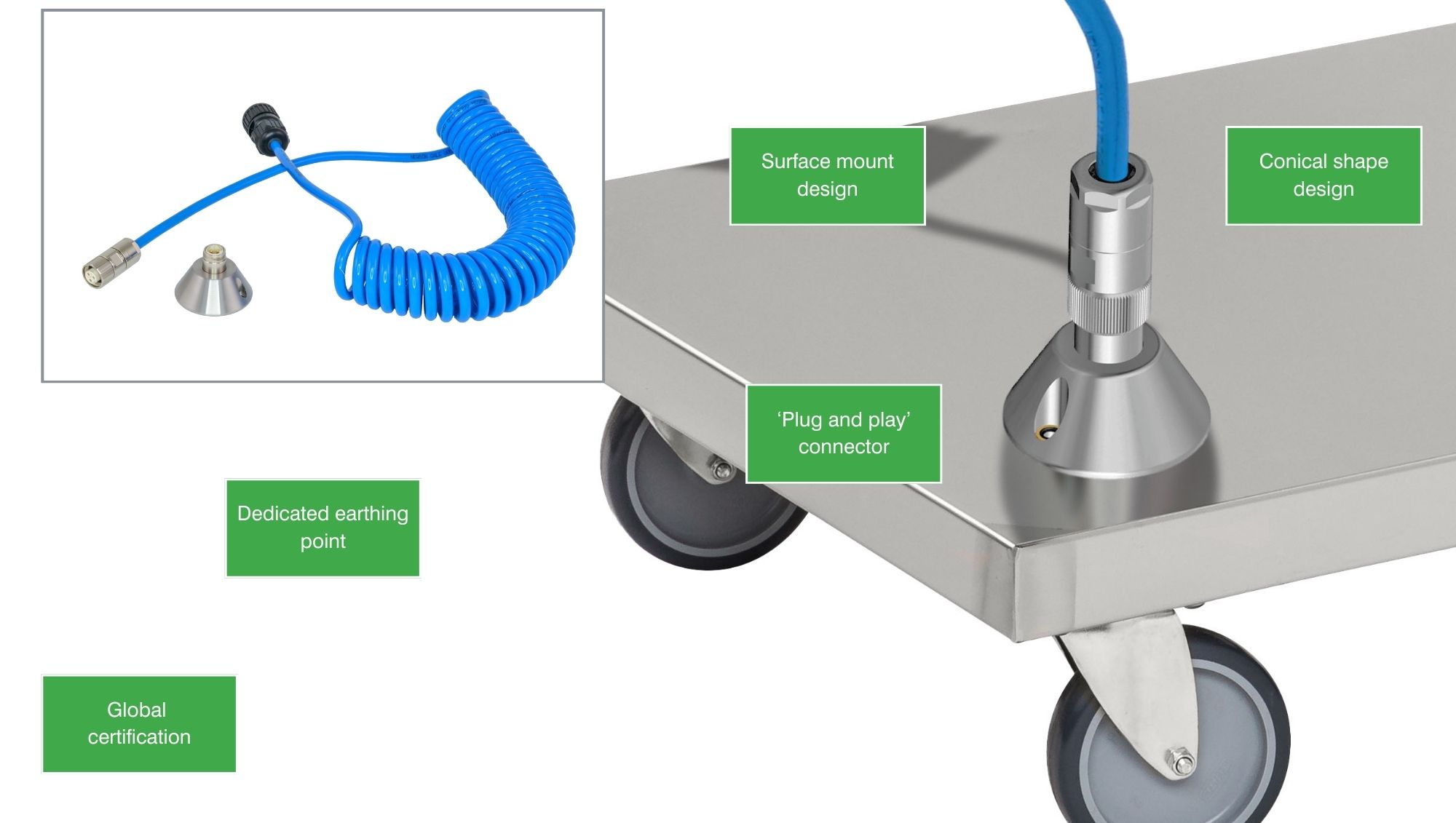

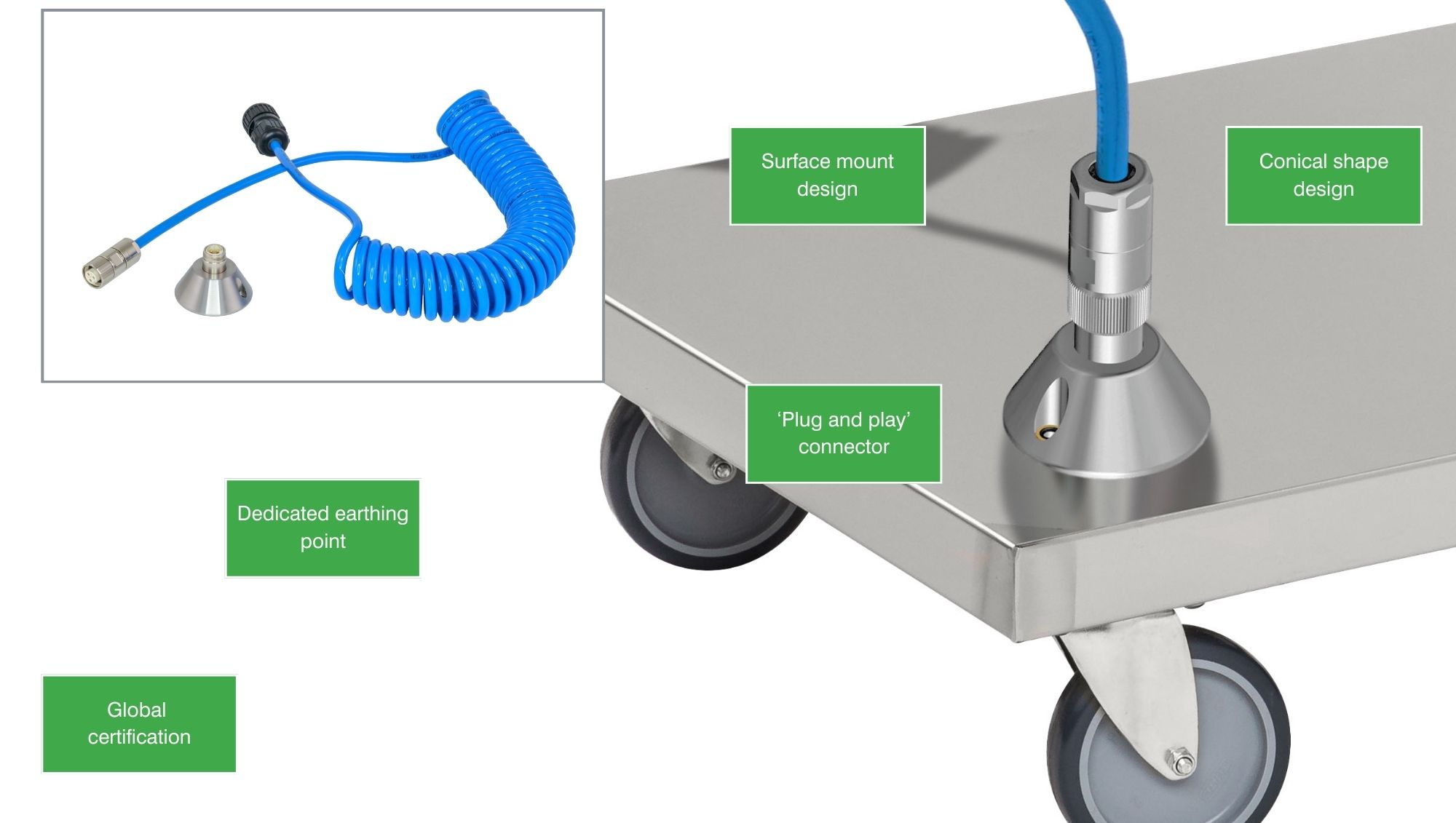

Surface Mount Grounding Connector

Intrinsically safe surface mount grounding connector

Offers a positive and secure contact with the equipment to be grounded, providing reliable grounding for safety.

The conical shape design aids in the reduction of powder deposit build up over time and aids in clean down operations.

UKCA and IECEx approved.

Operators tasked with earthing mobile process equipment will have a dedicated earthing point to attach the easy to use screw thread connector.

A dedicated earthing point on site with a screw thread connector. The ‘plug and play’ connector can interface with all Newson Gale dual core systems to provide earth monitoring capability on a wide range of mobile processes and equipment where generic earthing clamps cannot be used.

Surface Mount Connector static grounding clamp

| Applications: | Grounding and bonding metal objects such as large metal totes and IBCs |

| Clamp Material: | Stainless Steel (SS grade: 304 body) Viton (O-Ring) Polyacetal (Tip Housing) Tungsen Carbide Tip |

| Ingress Protection: | IP66 |

| Operating Temperature: | -40°C to +60°C |

| Dimensions: | 72 mm x 49 mm DIA |

| Weight: | 0.20 kgs (nett) |

| Cable Supplied: | 3 m (10 ft), 5 m (16 ft), 10 m (32 ft) or 15 m (50 ft) 2 pole Cen-Stat™ blue spiral cable with Hytrel® coating which has colour, UV protective and static dissipative additives |

| Wire Diameter: | Conductor cross sectional area – 1 mm² (11 AWG) approx. Copper With Cen-Stat™ coating – 7.5 mm (0.3”) diameter |

Dual core surface mount connector

Static grounding systems like the Bond-Rite® and Earth-Rite® range combine interlock control and visual indication to verified ground connection points and offer the highest levels of protection over electrostatic ignition risks.

Newson Gales’ approved surface mount grounding connector offers a positive contact with the equipment to be grounded. With this assembly operators tasked with earthing mobile process equipment will have a dedicated earthing point to attach the easy to use screw thread connector.

The ‘plug and play’ connector can interface with all Newson Gale dual core systems to provide earth monitoring capability on a wide range of mobile processes and equipment where generic earthing clamps cannot be used.

The conical shape design aids in the reduction of powder deposit build up over time and aids in clean down operations.

The static grounding connector is IECEx and UKCA approved and certified to ensure it is capable of dissipating static charges from potentially charged equipment.

Dedicated earthing point

Assembly operators tasked with earthing mobile equipment can install the surface mount connector to ensure a positive contact with the process equipment to be grounded.

What are the benefits of using tungsten carbide teeth?

Tungsten carbide is one of the hardest materials in use in industry today and when used in combination with a well designed clamp spring, has the capability to continuously bite through coatings, rust or product deposits that a basic alligator clip or welding clamp would struggle with. Sharpened tungsten carbide teeth are a standard feature of Newson Gale’s heavy duty clamps.

- Gain insights into the specification of hazardous area certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of Ex equipment.

- Evaluate competency requirements for individuals.

- Navigate Ex equipment documentations.

UKCA Certificates - United Kingdom

IECEx Certificates - International

Book a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of hazardous area classifications at your location. The most effective way to identify what is applicable for your operations is by talking to our team. They will provide in-depth information on the products, features and how the range of options can be tailored to your needs.