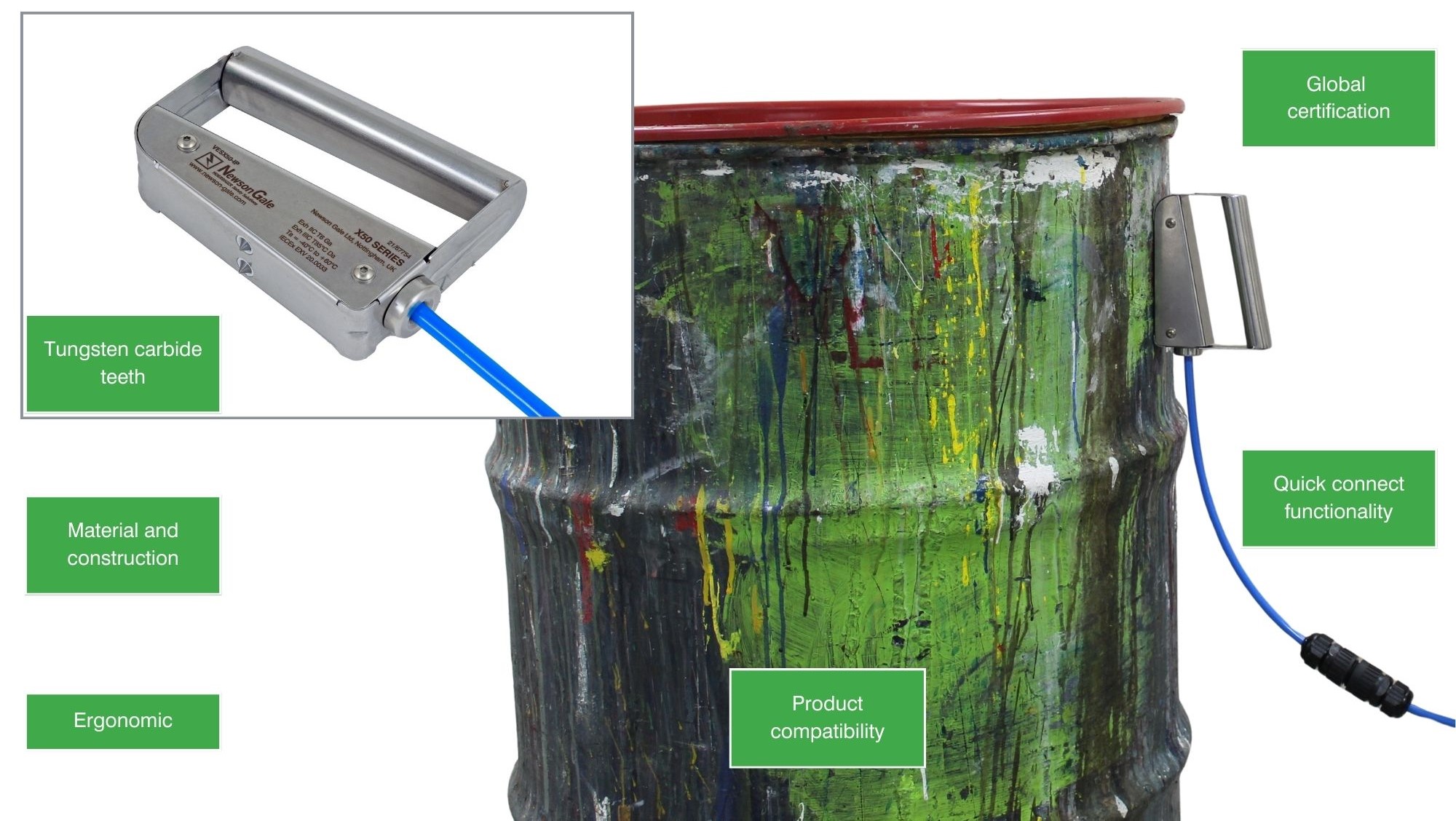

Magnetic Static Grounding Clamp

Intrinsically safe dual core static grounding clamp

Quick connect functionality for easy removal out of hazardous location.

UKCA and IECEx approved.

2 pole magnetic clamps have an integral handle and are therefore easy to grip, roll on and roll off when the operators have to make repetitive daily grounding connections.

Additional value is provided by the corrosion resistant and mechanically robust stainless steel construction which helps reduce long term replacement costs that are typical of lower quality grounding clamps.

The VESX50-IP 2 pole magnetic grounding clamp is fully compatible with the Newson Gale Bond-Rite® and Earth-Rite® monitoring systems that provide the customer with visual indication and interlock capability.

Overview of the Magnetic Static Grounding Clamp

The VESX50-IP magnetic static grounding clamp utilises magnetic technology to provide a strong and robust low resistance connection to any ferrous metal surface (body of a drum, container, IBC) without the reliance on an obvious clamping point, such as an earth pin, bar, tab. It also allows a connection method where the process does not allow a traditional earthing clamp to be fitted like closed drum filling or where mixing lids prevent a sound connection of a spring loaded clamp.

The stainless-steel grade 304 clamp body houses two Neodymium magnets and wiring.

Its powerful combination of sharp spring-loaded tungsten carbide teeth complemented by the strength of two neodymium magnets ensures that connection inhibitors such as paint coatings, product deposits or corrosion does not prevent the clamp from making a low resistance (10 ohms or less) connection to equipment due to be grounded.

Magnets have been incorporated into a wide-ranging number of applications in industries where they were not considered or used before, and this addition complements Newson Gale’s current range of both fixed Surface Mount Connector and mobile (Cen-Stat™ VESX45, VESX90) clamp connections with customers now able to benefit from more flexibility and variety when assessing the correct solution and ideal connection method for their application.

What are the benefits of using magnets?

Grounding clamps are typically designed around torsion or compression springs. The spring type grounding clamps are ideal for many different applications. However, attaching a spring based grounding clamp to a flat (metal IBC) or curving surface (body of a drum) is not normally possible.

Newson Gale have produced a dual core magnetic grounding clamp that capitalises on the power of magnetism to provide a strong low resistance connection (10 ohms or less) to any ferrous metal surface e.g. body of a ferrous metal IBC, drum, tote, etc. This will allow drums to be filled, the cover plate fitted over the open top complete with extract connection and still ground the ferrous metal based drum with the VESX50-IP dual core magnetic grounding clamp.

What are the benefits of using tungsten carbide teeth?

- Gain insights into the specification of hazardous area certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of Ex equipment.

- Evaluate competency requirements for individuals.

- Navigate Ex equipment documentations.

UKCA Certificates - United Kingdom

IECEx Certificates - International

Book a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of hazardous area classifications at your location. The most effective way to identify what is applicable for your operations is by talking to our team. They will provide in-depth information on the products, features and how the range of options can be tailored to your needs.