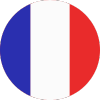

Earth-Rite® FIBC

Newson Gale’s dedicated Type C FIBC static earthing system

Checks the resistance (R ≤ 1 x 108 Ω) of the conductive or static dissipative elements of the bag specified in BS EN IEC 61340-4-4 “Electrostatic classification of flexible intermediate bulk containers (FIBC)”.

A version is available that tests R ≤ 1 x 107 Ω bags if required.

Monitors the resistance through the Type C bag to the static ground point for the duration of the bag filling/emptying procedure.

7 year warranty against manufacturer’s defects on PCBs.

1 year warranty on mechanical parts.

The system is ready for use “out of the box” – there is no requirement to calibrate the system at the point of installation or throughout its useful lifetime.

Can be supplied with a dedicated Tester that will enable regular checking of the active ground monitoring circuit to demonstrate it is operating within original factory parameters.

Two pairs of NO/NC volt free contacts, one x intrinsically safe output contact (optional).

Can be interlocked with automated bag filling/emptying systems or any other control equipment.

Attaching the clamps on the top and bottom tabs of the bag monitors the resistance of the conductive thread/s or filaments between them and the ground point.

Provides operators with the solution of not needing to use the bag’s lifting hooks as a fortuitous static dissipation path (which is prohibited by BS EN IEC 61340-4-4).

Overview of the Earth-Rite® FIBC

Operation

In line with recommended practice, it is advisable that plant operators follow a simple protocol of “Clamp On First, Clamp Off Last” (CoF/CoL). This should, wherever possible, be incorporated into the process operator’s SOP.

The following conditions must be satisfied before the Earth-Rite® FIBC will indicate a permissive condition to process operators:

- The resistance between the bag’s earthing points and the conductive filaments of the Type C FIBC is ≤ 1 x 108 Ω

- The resistance of the conductive woven threads or filaments through the bag is ≤ 1 x 108 Ω

- The Type C FIBC is connected to a verified earth point.

Intrinsically safe (I.S.) active earth monitoring circuit

To remove any level of doubt with respect to the Ex zoning of the bag, the Earth-Rite FIBC® system utilises an intrinsically safe (I.S.) earth monitoring signal with the highest level of Ex protection “Ga” and “Da” which can be used in Zone 0/20 atmospheres and all gas, vapour and dust groups.

In addition to determining if the resistance through the bag is below the specified upper resistance threshold of 1 x 108 Ω, the Earth-Rite® FIBC system actively monitors the Type C FIBC bag’s connection to the plant’s verified earthing point.

This feature determines if the Type C FIBC bag has a monitored connection to a verified earth, which enables the dissipation of electrostatic charge from the bag for the duration of the filling/emptying operation.

There may also be occasions, e.g., after filling, where the Type C FIBC bag continues to be earthed by the system to enable the migration of charge from high resistivity materials via the conductive/static dissipative elements of the bag to earth. If this is the case, an SOP should be developed that incorporates a specified charge relaxation time for the material being processed.

The intrinsically safe earth monitoring circuit remains active for the duration of the bag filling/emptying process.

Two earthing clamps

The unique shape of the nylon serrated block, coupled with the rounded contact, allows the VESX45-F clamp to be applied to Type C earthing tags located on Type C FIBC bags. The grip provides a firm, fixed connection to the tag without causing damage or compromising the continuity of the tag, increasing service life of the bag.

Note: Never attach the monitoring clamp and the earth clamp to the same tag on the Type C FIBC bag.The Earth-Rite® FIBC system is supplied with a pair of earthing clamps as standard. There are several benefits associated with this feature.

To determine if the resistance of the static dissipative material of the bag meets the ≤ 1 x 108 Ω resistance threshold requirement specified in BS EN IEC 61340-4-4, it is more beneficial to direct the monitoring circuit of the Earth-Rite® FIBC through the bag. If you only check the connection to the designated earthing point of the bag via a single clamp, this would only indicate if the designated earthing point of the bag is static dissipative, as monitoring through the bag cannot be verified.

The monitoring clamp directs the intrinsically safe earth monitoring signal from the Earth-Rite® FIBC system to a designated earthing point on the bag. By imposing a return path for the monitoring signal through the bag, it provides a good indication as to whether the resistance through the bag is in line with the standard. If the static dissipative content of the bag is less than the specified threshold of ≤ 1 x 108 Ω, the second clamp, called the “earth clamp” channels the signal back to the Earth-Rite® FIBC system, via the plant’s designated earthing point. Any electrostatic charge at risk of accumulating on the bag is transferred to earth via the earth clamp.

The benefit of providing two clamps is that it enables a broader test of the static dissipative structure of the bag. Ideally, with one clamp attached to the bottom of the bag and the other attached to the top of the bag, to verify if the designated earthing points on the bag are electrically connected to the static dissipative material of the bag (e.g., threaded filaments).

The earth clamp, VESX45-FE (a fully conductive variant of the VESX45-F), is specifically designed to provide a reliable earth return path back to the earthing network. Attach the earth clamp onto the top earthing tag of the Type C FIBC bag. Ideally, position the clamp diagonally to the monitoring clamp to ensure optimal path coverage.

Note: It is always recommended to use the dedicated earth clamp to provide reliable earthing of the bag.The gripping pressure applied by the clamps to the bag’s designated earthing points, once they are connected by the operator, is sufficient for making good electrical and mechanical contact with the earthing points located on the bag.

However, care should be taken to ensure that the cables are not overstretched (e.g., by selecting too short a length of cable) or do not become disconnected, i.e., by hitting the bag or moving the bag in an aggressive manner to dislodge the product, which may have solidified inside the bag.

The standard also states that the bag’s lifting hooks, even if they are made of conductive or static dissipative material, cannot be used as fortuitous earth connection points for the bag, i.e., points that transit electrostatic charge from the bag to earth. The use of lifting hooks, in this context, can be avoided by providing a second clamp that can be attached to a separate designated earthing point on the bag.

As is the case with any electrical circuit, it is worth noting that the monitoring signal of the Earth-Rite® FIBC will take the path of least resistance through the bag, hence, it is virtually impossible to test all the static dissipative material from which the bag is constructed.

Periodic testing of bags subjected to frequent use or contamination should be carried out in line with Clause 9 of the BS EN IEC 61340-4-4 product standard for FIBC. The Type C bag manufacturer should be able to advise on recommended testing intervals.

Easy to operate

The design of the user interface focuses on simplicity and ease of interpretation. A positive or negative state is provided by a cluster of red and green LED indicators which promotes a simple but effective traffic light principle of “GO/NO-GO”, indicating if the process, in this case bag filling or emptying, can take place.

When the correct resistance threshold is achieved, the three green flashing LEDs indicate that the system is actively monitoring the resistance through the bag and the bag’s connection to the verified earthing point throughout the process.

The operator activates the Earth-Rite® FIBC system by simply connecting both clamps to the Type C bag. The clamps should be connected to designated points located at the bottom and top of the bag, respectively. Once connected, the operator will be able to observe if a permissive condition is indicated by the LED indicators.

Interactions with switches, dials, calibration devices or the interpretation of resistance meter readings are not required. If the flashing green LEDs are activated, the operator can move on to the next step of the bag filling/emptying procedure.

Output contacts

Two pairs of voltage-free NO/NC contacts, or an optional single I.S. switching contact, can be selected for controlling equipment external to the system. If an automated bag-filling/emptying system is being used, the Earth-Rite® FIBC system can be interlocked with the PLC controlling the process so that a permissive condition must be achieved in advance of the bag-filling/emptying process taking place.

Please note that in an emergency shutdown scenario, e.g., the connection to earth has been compromised during the bag filling/emptying procedure, the product may continue to flow into or out of the bag once the bag filling process has begun. This could lead to the accumulation of static electricity on the FIBC. If a HAZOP assessment highlights the potential for such a scenario to occur, additional measures may need to be put in place.

For example, it may be possible to determine the charge relaxation time of the material and issue an SOP to operators so that they do not approach the FIBC during the specified time period. Site operators should retain the services of a static control consultant if this scenario could arise.

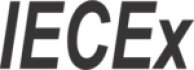

Installation

Please note that an Ex-competent person is required to carry out the installation of Ex-certified products. If you have any doubts with respect to the installation requirements of Newson Gale equipment in EX atmospheres, one of our CompEx certified engineers will be happy to support you.

The Earth-Rite® II FIBC system is easy to install and does not require any calibration of the monitoring circuit at the point of installation. The system can be powered by 115v/230v AC mains power or 12v/24v DC power.

If the EX atmosphere is dust only, a static dissipative GRP enclosure can be selected for installation in a Zone 21 or Zone 22 location.

If the atmosphere is classified as having the potential for the presence of both a combustible dust and vapour atmosphere, an Ex d enclosure can be specified, as this will satisfy the requirements for both gas and dust atmospheres. Please refer to the technical specifications below.

As the earth monitoring circuit is certified as intrinsically safe, with the highest protection level “Ga”/“Da”, both earthing clamps can be used in a Zone 0 or Zone 20 location, as they will be in close contact with the bag and the potentially higher concentrations of dust and vapour atmospheres. An important point to note is that both clamps are not composed of any insulating materials that exceed the guidance in IEC TS 60079-32-1 or specified in the EX standard IEC EN 60079-0, so they can be used in all gas/vapour EX zones.

An installation kit consisting of glands and cabling specific to the enclosure selected and the hazardous area classification can be specified with the system.

Please Note:

- It is the site operator’s responsibility to provide the verified earthing point for the Earth-Rite® FIBC system.

- The Earth-Rite® FIBC must be installed as per the Newson Gale Instruction Manual.

- Gain insights into the specification of hazardous area certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of Ex equipment.

- Evaluate competency requirements for individuals.

- Navigate Ex equipment documentations.

UKCA Certificates - United Kingdom

ATEX Certificates - Europe

IECEx Certificates - International

cCSAus Certificates - United States

CCC Certificates - China

KCs Certificates - South Korea

P1 = one GRP enclosure

Book a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of hazardous area classifications at your location. The most effective way to identify what is applicable for your operations is by talking to our team. They will provide in-depth information on the products, features and how the range of options can be tailored to your needs.