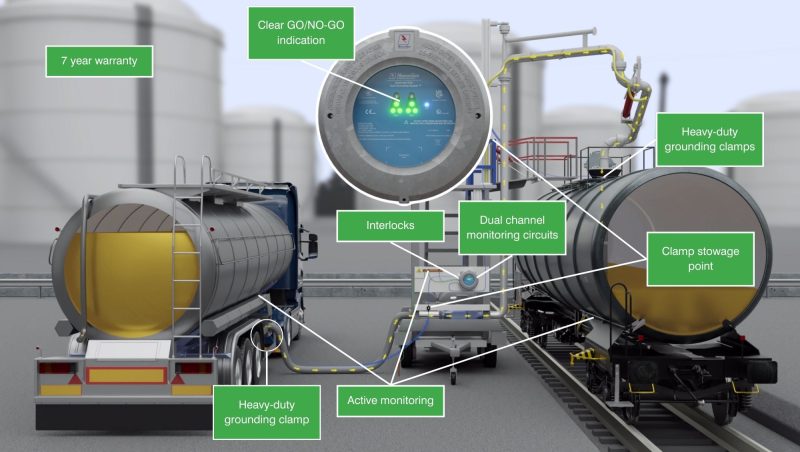

Earth-Rite® DGS

Newson Gale’s dual grounding system with system interlocks and visual indication

Actively monitors the resistance of the circuit between the rail tanker, road tanker and the loading gantry’s verified earthing point to 10 ohms or less.

DOES NOT require calibration at installation or throughout its lifecycle.

Utilises heavy-duty stainless-steel clamps, that combines sharp tungsten carbide teeth with a strong torsion spring to establish, and maintain, a positive connection to the rail tanker for the duration of the loading/unloading operation.

Grounding clamps DO NOT contain any insulating materials (rubber/plastic) that exceed the volume or surface area for Ex areas as specified in IEC TS 60079-32-1 (does not require rubber handle).

7 year warranty against manufacturer’s defects on PCBs.

1 year warranty on mechanical parts.

Overview of the Earth-Rite® DGS

The Earth-Rite® DGS (Dual Grounding System) has two independent earth monitoring circuits that allow operators to earth and continuously monitor two items of metal conductive plant equipment concurrently to 10 ohms or less, such as two bulk transportation vehicles or other metallic vessels like Ex IBCs and metal drums. This feature is commonly used to earth trucks and railcars during transloading operations or to earth up to two trucks or railcars that are being loaded/unloaded at dedicated loading rack installations.

Interlocking the earthing system with the process equipment being used enhances the safety and operating procedure before the process starts. If the earth connection is lost, the Earth-Rite® DGS can shut down the process for one or both of the channels.

Interlocking the earthing system with strobes provides personnel working in the surrounding area with a clear view of when the earthing process is underway and protected.

Dual earthing and monitoring channels

The Earth-Rite® DGS enables the earthing and control of two processes with a single system, using its dual earthing and monitoring channels. Both channels can monitor independent loops to 10 ohms or less from the vessels to a common verified earth bar via an intrinsically safe Ex ia circuit. This solution provides a secure transloading process when transferring materials from one container to another during metering or processing.

Interlock capabilities

The hazardous area approved system can interlock with on-board control equipment such as pumps, PLCs, and valves to prevent the flow of product before reliable earthing is in place, ensuring a safe working procedure is followed prior to any other processes taking place.

Once both the road tanker and rail car have been successfully earthed, all interlocks will be energised and high-intensity green LEDs on the system enclosure will flash, giving the operator the go-ahead to begin the product transfer.

A failure to detect a path to earth of 10 ohms or less at any time, for example by removing the clamp, will safely shut down the transfer of product provided it is interlocked correctly through the PLC or pump control system.

Typical applications

Installation

Installing an Earth-Rite® DGS system onto the mobile transloader allows a portable earthing system to be taken alongside the process equipment wherever it’s needed.

Certification allows for installation into a Zone 1/21 hazardous area.

Please note that an Ex-competent person is required to carry out the installation of Ex-certified products, as per the product manual. If you have any doubts with respect to the installation requirements of Newson Gale equipment in Ex atmospheres, one of our CompEx certified engineers will be happy to support you.

- Gain insights into the specification of hazardous area certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of Ex equipment.

- Evaluate competency requirements for individuals.

- Navigate Ex equipment documentations.

UKCA Certificates - United Kingdom

ATEX Certificates - Europe

IECEx Certificates - International

cCSAus Certificates - United States

CCC Certificates - China

KCs Certificates - South Korea

Book a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of hazardous area classifications at your location. The most effective way to identify what is applicable for your operations is by talking to our team. They will provide in-depth information on the products, features and how the range of options can be tailored to your needs.