Bond-Rite® REMOTE

Newson Gale's continuous earth loop monitoring solution with visual indication

The Bond-Rite® monitors the resistance between the clamp teeth back to the ground bar to 10 ohms or less and cannot be adjusted by operators.

DOES NOT require calibration at installation or throughout its lifecycle.

Utilises a heavy-duty stainless-steel clamp, that combines sharp tungsten carbide teeth with a strong torsion spring to establish, and maintain, a positive connection to the metal object (e.g., drums) for the duration of the loading/unloading operation.

Grounding clamps DO NOT contain any insulating materials (rubber/plastic) that exceed the volume or surface area for Ex areas as specified in IEC TS 60079-32-1 (does not require rubber handle).

The remote power supply unit can be mounted in Zone 2/21 areas. Refer to technical specification for additional Ex certification details.

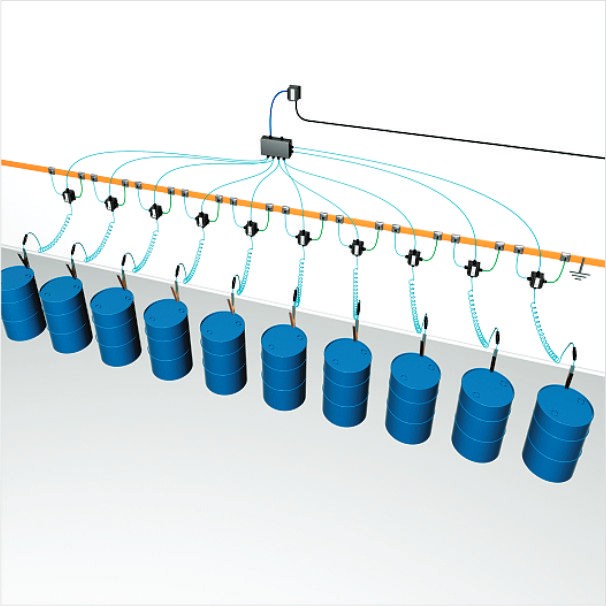

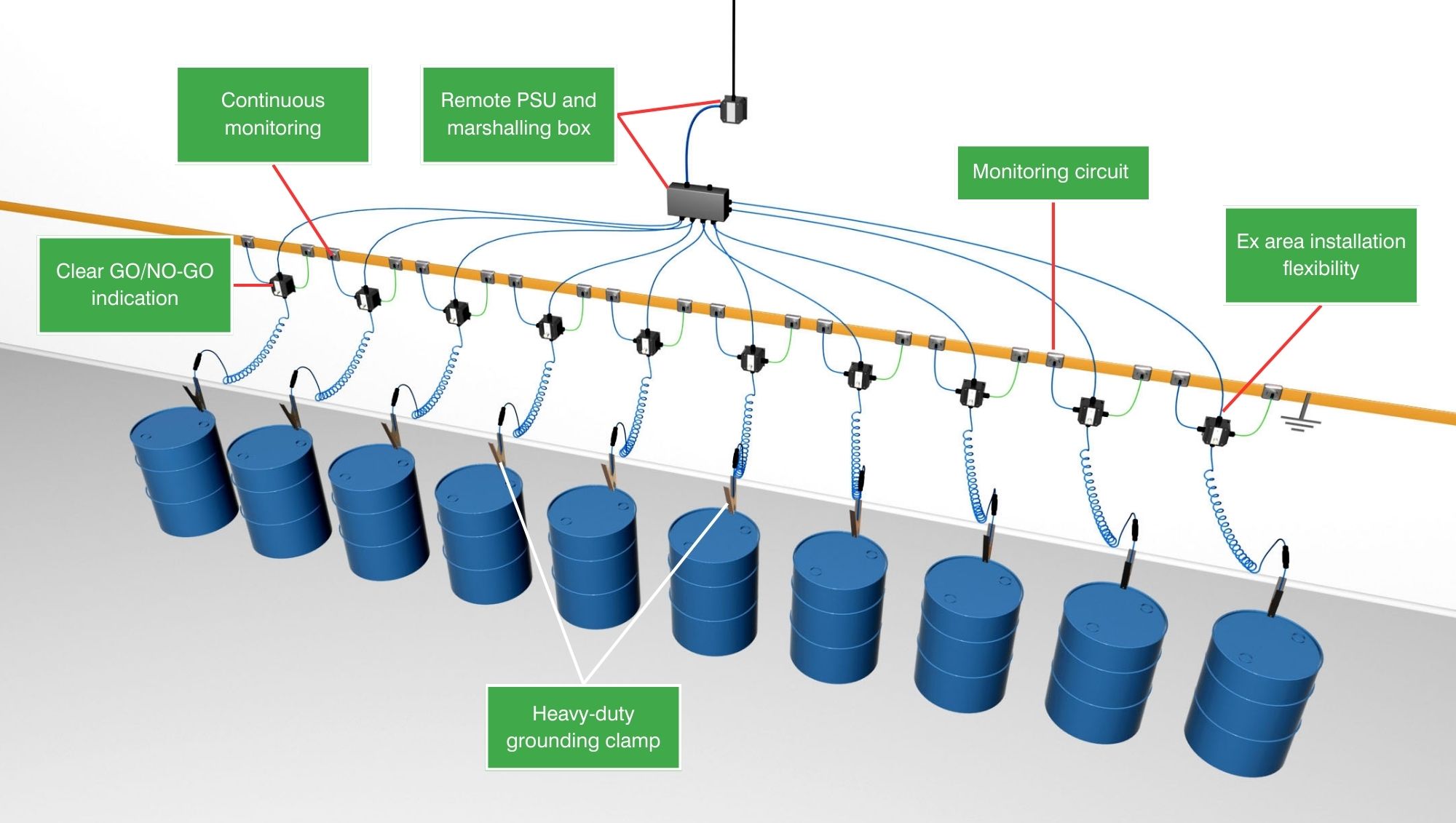

The marshalling box can be installed in Zone 0/20 and distribute power to up to 10 Bond-Rite® REMOTE units.

GRP

Bond-Rite® REMOTE [GRP] – Battery Powered and Mains Powered

| Ingress Protection: | IP65 |

| Ambient Temperature Range: | -40°C to +60°C |

| Monitored Loop Resistance: | Nominally ≤10 Ω (±10%) |

| Indicator Lamp LED: | 1 green |

| Battery Supply Option: | Varta 6122 E-Block (9V Lithium-Manganese Battery) supplied with unit |

| Power Supply Option: | Newson Gale Universal Power Supply |

| Enclosure Material: | Glass Reinforced Plastic (carbon loaded) |

Stainless Steel

Bond-Rite® REMOTE [Stainless Steel] – Battery Powered and Mains Powered

| Ingress Protection: | IP65 |

| Ambient Temperature Range: | -40°C to +60°C |

| Monitored Loop Resistance: | Nominally ≤10 Ω (±10%) |

| Indicator Lamp LED: | 1 green |

| Battery Supply Option: | Varta 6122 E-Block (9V Lithium-Manganese Battery) supplied with unit |

| Power Supply Option: | Newson Gale Universal Power Supply |

| Enclosure Material: | Stainless steel (SS grade: 304) |

Overview of the Bond-Rite® REMOTE

The Bond-Rite® REMOTE provides additional levels of flexibility for Ex-hazardous area installation.

This wall-mounted version of the Bond-Rite® range can be specified for application scenarios where there is a preference to have the earth status indication located in positions where it is easier to observe the LED indicator and/or prevent covering of the LED caused by product splashing/spillages, which could impair the visibility of the LED indicator mounted in the Bond-Rite® CLAMP.

Primary benefits of the Bond-Rite® REMOTE

The primary benefits of the Bond-Rite® REMOTE:

- The Bond-Rite® REMOTE continuously monitors the electrical resistance between the object to be earthed and the plant’s verified earth point. The resistance threshold of 10 ohms or less is adopted to align with IEC TS 60079-32-1 (and PD CLC/TR 60079-32-1).

- Operators are provided with a simple “GO/NO-GO” method of indication via a highly visible flashing green LED located in the wall-mounted enclosure. The operators do not need to be trained to use Ex multi-meters, which can be complex and costly.

- Periodic electrical resistance checks of non-monitored basic clamp, cable, and reel connections by maintenance engineers are not required. The Bond-Rite® checks the condition of the earth circuit on a continuous basis when in use.

- The Bond-Rite® resistance threshold is set at 10 ohms or less and cannot be adjusted by operators.

The Bond-Rite® is designed to be easy to understand and use. - The Bond-Rite® does not require calibration.

- The Ex certification permits the use of the Bond-Rite® REMOTE in the highest hazardous area zones (Zone 0/20) due to its intrinsically safe Ex ‘ia’ monitoring circuit.

- The remote power supply unit can be mounted in Zone 2/21 areas. Refer to the technical specification for additional Ex certification details.

Connection to the metal object to be earthed is provided by a clamp with a high-strength torsion spring and a pair of tungsten carbide teeth designed to bite through layers of deposits like rust, paint, and product deposits that could impede the transfer of electrostatic charges.

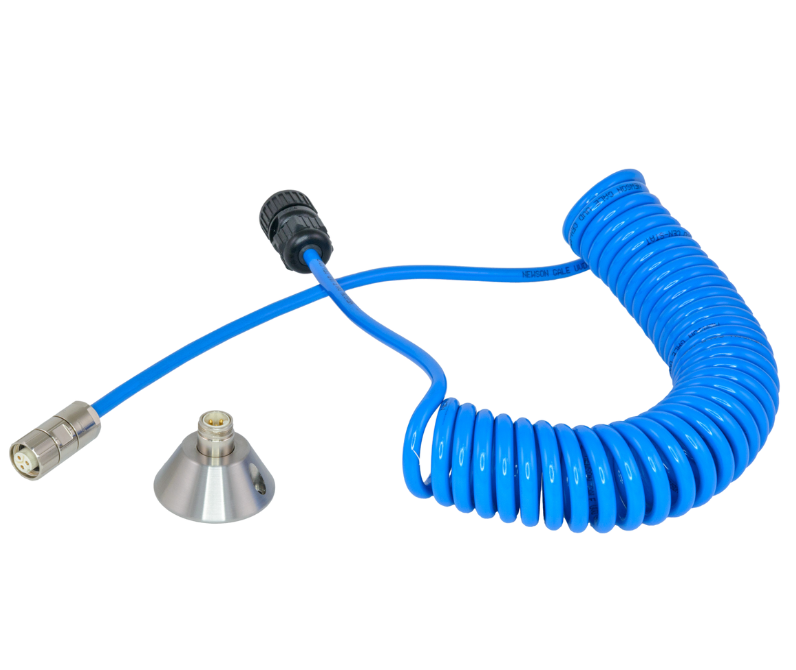

Depending on the application requirements, the magnetic clamp or surface mount connector could alternatively be used.

Additional product flexibility

Depending on the connection requirements to plant equipment, several flexible options can be specified.

- Large or medium-sized heavy-duty clamps.

- A magnetic clamp.

- A 2-pole surface mount connector.

Further flexibility is provided with the option of using 2-core spiral and straight cables of various lengths or a 15-meter 2-core cable reel.

Monitoring circuit

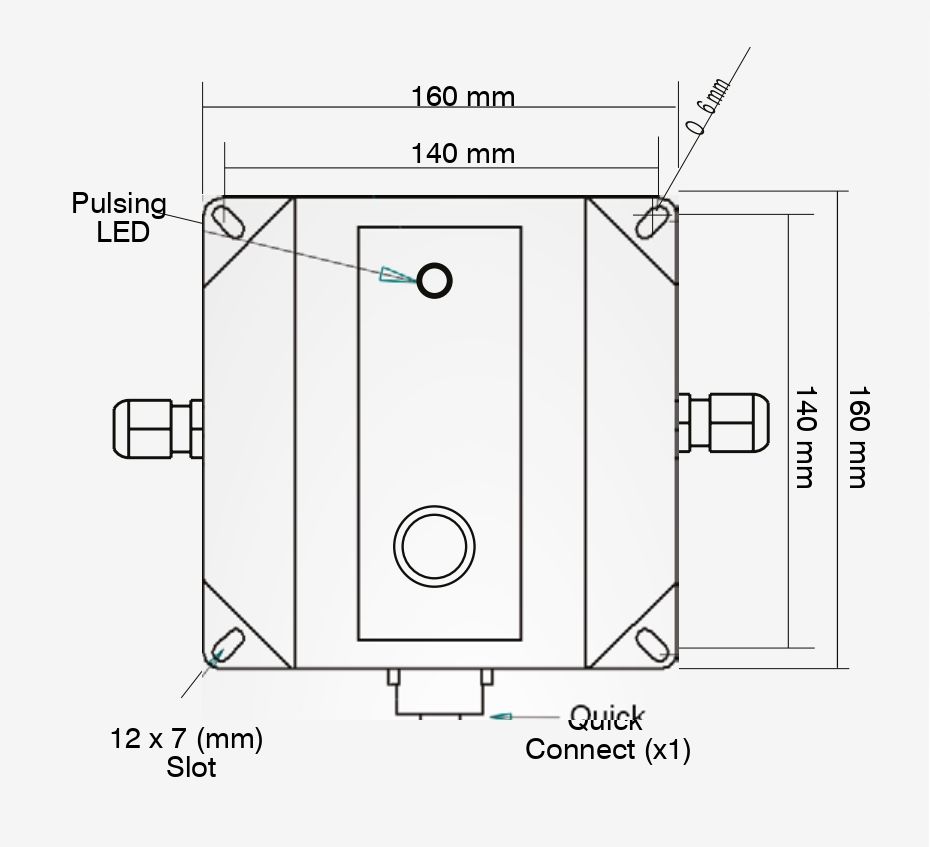

The intrinsically safe monitoring circuit can be located in a GRP or stainless-steel enclosure that can be mounted on walls and gantries within the hazardous area.

Quick and easy installation is provided when the 9V battery version of the Bond-Rite® REMOTE is specified, as there is no need to power it from the plant’s power supply.

However, if there is the possibility that the Bond-Rite® REMOTE will be used over long time periods that could result in potentially frequent battery replacement, the Bond-Rite® REMOTE can be specified with our Ex-certified 115v/230v AC power supply unit.

The power supply unit can power up to 10 Bond-Rite® REMOTE indicator stations simultaneously by its intrinsically safe Ex ia output. One of the main advantages of the remote power supply unit is the option to mount it in the hazardous area Zone 2/21, providing added installation flexibility.

- Gain insights into the specification of hazardous area certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of Ex equipment.

- Evaluate competency requirements for individuals.

- Navigate Ex equipment documentations.

UKCA Certificates - United Kingdom

ATEX Certificates - Europe

IECEx Certificates - International

cCSAus Certificates - United States

CCC Certificates - China

KCs Certificates - South Korea

UPS = Universal Power Supply

Book a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of hazardous area classifications at your location. The most effective way to identify what is applicable for your operations is by talking to our team. They will provide in-depth information on the products, features and how the range of options can be tailored to your needs.