Static Earthing Protection for Road Tankers

How do Grounding and Earthing mitigate static discharge?

Why and how is static electricity an ignition source for Road Tankers?

Summary: Static Earthing Protection for Road Tankers

Static earthing (grounding) is essential for the safe loading and unloading of road tankers transporting flammable liquids or powders. As these materials move, they can generate electrostatic charges that, if not safely dissipated, may cause dangerous sparks and ignite explosive atmospheres. Because road tankers are mobile and often isolated from permanent grounding networks, temporary but reliable earthing solutions are required during transfer operations.

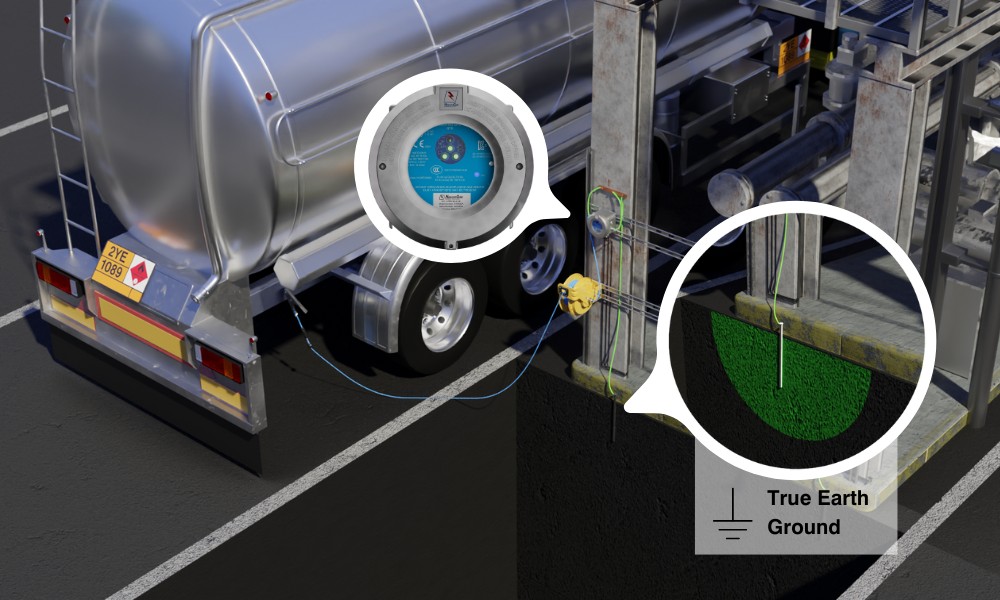

Industry standards, such as IEC TS 60079-32-1, recommend that the resistance between a road tanker and a verified earth point should be less than 10 ohms. All metallic components of the tanker must be bonded together to prevent isolated charge buildup. Advanced systems like Newson Gale’s Earth-Rite® RTR continuously monitor earthing resistance, ensuring compliance and activating interlocks if safe thresholds are exceeded.

Proper static earthing protects operators, equipment, and the environment by minimising the risk of static-induced ignition. Regular checks and high-quality grounding solutions are critical to maintaining safety and meeting regulatory requirements in hazardous environments.

In processes involving the movement of liquids and powders, electrostatic charge generation could occur. Metal equipment could accumulate an electrostatic charge if they are not connected to the general mass of the earth.

Because most of the equipment referenced can be moved or is designed to move, this prevents permanent connections to the general mass of earth through installed grounding networks and building structures.

This is true in applications requiring static earthing for road tankers, where mobility and frequent transfer operations demand reliable, temporary grounding solutions, Therefore, temporary connections to earth should be made when the process is underway to mitigate an uncontrolled electrostatic discharge.

A target threshold resistance of 10 ohms between the equipment and a verified true earth grounding point is recommended in a wide range of industry publications.

Earthing of Road Tankers - what are the standards saying?

Wherever possible, Newson Gale adopts guidance on electrostatic hazards from standards publishing institutions that can help define the parameters for effective earthing and bonding in EX atmospheres.

The Earth-Rite® RTR system from Newson Gale detects the capacitance of a typical road tanker and provides true earth verification.

In IEC TS 60079-32-1 “Explosive atmospheres – electrostatic hazards, guidance”, the guidance with respect to the loading (or unloading) of road tankers states the following:

7.3.2.3.3 Precautions for road tankers

“The precautions for road tankers are the same as for fixed tanks (7.3.2.3.2) except for the use of different velocity limits as described in 7.3.2.3.5.4 and the following additional requirements:

1) Earthing and bonding:

- a) The bonding resistance between the chassis, the tank and the associated pipes and fittings on the truck should be less than 1 MΩ. For wholly metallic systems, the resistance should be 10 Ω or less and if a higher value is found further investigations should be made to check for possible problems of e.g. corrosion or loose connection.

- b) An earthing cable should be connected to the truck before any operation (e.g. opening man lids, connecting pipes) is carried out. It should provide a resistance of less than 10 Ω between the truck and the gantry’s designated earthing point and should not be removed until all operations have been completed.

- c) It is recommended that the earth cable required in b) be part of a static earth monitoring system that continuously monitors the resistance between the truck and a designated earthing point on the gantry and activates interlocks to prevent loading when this resistance exceeds 10 Ω.”

Recommended Solution:

Sources of electrostatic charge accumulation

When electrically insulating liquids and powders move through a system of pipes, filters, meshes, pumps, and so forth, the interaction with the equipment can charge the material as it moves through the system.

If the electrostatically charged material is transferred into or out of an unearthed road tanker, the electrical potential (voltage) of the road tanker can rise rapidly. If the voltage on the road tanker exceeds the breakdown voltage of the surrounding atmosphere, then the risk of an incendive electrostatic spark is significant.

The breakdown voltage of air is in the region of 3 kV/mm, and if an ignitable gas, vapour, or dust atmosphere is present in the spark gap at the time of discharge, then ignition is very probable. Sparks can be discharged from the tank/chassis of the road tanker, or components attached to the road tanker, onto objects like hoses, filling pipes, loading gantry equipment, and operators etc.

Road tanker capacitance

Because sparks from isolated metal objects have a high level of energy concentrated in a single discharge, all metallic parts of a road tanker (chassis, tank, pipe fittings, and hose trays, etc.) should be bonded together with a resistance of 10 ohms or less (ref: per 1a above).

This should prevent electrical isolation of metallic parts of the vehicle that could otherwise accumulate electrostatic charge. What cannot be avoided, however, is the potential electrical isolation of the road tanker body during loading and unloading procedures.

The electrically insulating properties of road tanker tyres could isolate the road tanker body from the general mass of the earth. When the road tanker is receiving or offloading insulating materials, the metal body of the road tanker (chassis, tank body, etc.) can develop very high voltages.

By connecting the road tanker to the general mass of the earth, spark discharges from the body of the road tanker can be avoided.

Static Earthing Road Tankers: Why is proper earthing critical for Road Tanker safety?

Earthing (sometimes known as grounding) the road tanker means that we are effectively connecting the structure of the road tanker to the general mass of earth. It is assumed that no metallic parts like valves, lids, etc., are electrically isolated (R > 10 ohms) from the main structure of the road tanker. It is generally accepted that most of the resistance in the path to earth will be between the earth electrode buried in the soil and the layers of resistance present around the soil to the general mass of the earth.

While a theoretical value of 1 megohm is often cited as the upper threshold at which static charge will flow to the mass of earth, the electrical connections from the road tanker to the earth electrode should be 10 ohms or less. If the electrical resistance in the circuit is higher, there is likely to be loose or corroded connections in the path for the charges to “travel” to earth. If there are mechanical breakages at these points, they could present as spark gaps in the EX area.

13 Earthing and bonding (IEC 60079-32-1)

“By far the most effective method of avoiding hazards due to static electricity is to connect all conductors to earth. This will avoid the most common problem which is the accumulation of charge on a conductor and the release of virtually all the stored energy as a single spark, to earth or to another conductor …

…The total resistance between an earthed object and the ground is the sum of the individual resistances of the earth wire, its connectors, other conductive materials along the intended earthing path, and the resistance of the earth electrode (i.e. earth rod) to the ground.

Most of the resistance in an earth connection may exist between the earth electrode and the earth itself. This earth resistance is quite variable because it depends on the area of contact, the resistivity of the soil, and the amount of moisture present, temperature, etc in the soil …

13.2.2. Metallic items in good contact with earth should have a resistance to it of less than 10 Ω. Although a value of up to 1 MΩ is acceptable for static dissipation, values above 10 Ω may give an early indication of developing problems (e.g. corrosion or a loose connection) and should be investigated. It is important that all connections are reliable, permanent and not subject to deterioration.”

Note: If electrostatic charging of liquids is high enough, there is a possibility that brush discharges could occur from the surface of an insulating liquid inside the road tanker.

Earthing the road tanker to prevent static sparks, which are high-energy electrostatic discharges, may prove inadequate with respect to the avoidance of electrostatic brush discharges from the liquid itself. A thorough HAZOP of the process and material is advisable to rule out such concerns. Earthing of the road tanker should be carried out as this will mitigate against the risk of static sparks.

Care must also be taken to ensure no conductive items (e.g., empty cans or sampling cups) are floating on the surface of the liquid in case they discharge static sparks to other objects like the inner wall of the tank, which should be earthed.