Static Earthing for Portable Containers

Solutions for metal drums and EX IBCs ranging from 205 litre to 1000 litre capacity

Portable containers in the 205 litre to 1000 litre capacity range

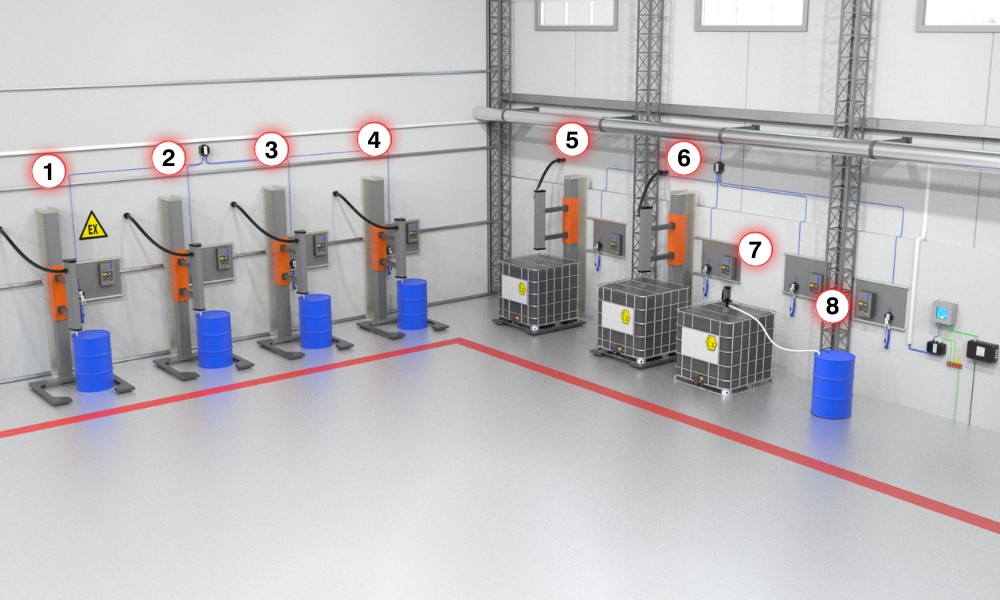

Metal drums and EX IBCs are containers that provide site operators with a flexible means of transporting and processing batch quantities of products. Operations ranging from mixing, agitation and blending to the filling and emptying of low conductivity liquids can result in the generation of static electricity, leading to the accumulation of electrostatic charge on the container if it is not earthed. If electrostatic charge is permitted to accumulate on the container, the risk of an incendive static spark discharge to objects at a different potential, like operators and other plant equipment, is a high possibility. If a flammable atmosphere is present at the static spark discharge location, then ignition is very possible.

The processes associated with metal drums and EX IBCs in the 205 litre to 1000 litre range normally rely on the use of pumping or mixing equipment. Site operators have the option of specifying active earthing systems that feature output contacts that can be interlocked with the process equipment*. In this scenario, the mixing or pumping process cannot take place unless the earthing system confirms that the metal drum or EX IBC has a connection to the site’s designated earth with a resistance of 10 ohms or less.

* Assumes the earthing system is installed as per the accompanying Instruction Manual.

Static Earthing Recommended Solutions:

Different types of IBCs and drums

The range of materials that make up the construction of IBCs and drums needs to be assessed by site operators when trying to mitigate the risk associated with static electricity.

The use of plastic, a naturally low conductivity material, whether it be used as a vessel for IBCs, or as a liner inside metal drums, is a factor that needs to be considered. The use of static dissipative plastics has also increased over the last 10 to 15 years. As such, there is a multitude of “composite” drums and IBCs being used in EX atmospheres today.

Wherever possible, Newson Gale adopts guidance on electrostatic hazards from standards publishing institutions and industry bodies that can help define the parameters for effective earthing and bonding in EX atmospheres.

As Newson Gale is not a static control consultancy, we cannot recommend any specific types of containers for different processing applications, but if IBCs with plastic containers are a process requirement (e.g., for material compatibility reasons), please consult Section 7.3.4 of IEC TS 60079-32-1 alongside an on-site risk assessment. Wherever possible, the use of low-conductivity plastic should be avoided.

ESIG, the European Solvents Industry Group, has a free downloadable guide for site operators engaged in the processing and transportation of solvents.

This document provides practical guidance on the different types of IBCs and drums in use within the solvents industry.

If you require a static control solution for metal drums or IBCs that are of a static dissipative construction, please contact us for solutions that can actively monitor at resistance thresholds higher than 10 ohms.

EX IBCs

In relation to the static earthing of Ex IBCs it promotes a “Clamp On First, Clamp Off Last” protocol:

3.3.6.2 Filling IBCs

“The first step in loading all IBCs should be to attach a temporary earth connection with a maximum resistance of 10 Ω to the frame or earth point. The final step should be the removal of this earth connection.”

Section 7.3.2 of IEC TS 60079-32-1, called “Small conductive tanks and containers”, addresses some of the complexity associated with the construction of drums and Ex IBCs.

These containers are defined as having volumes ≤ 2 m3 and an effective diameter of ≤ 1.3 m. From a static earthing perspective any conductive and dissipative material must be earthed.

Metal drums

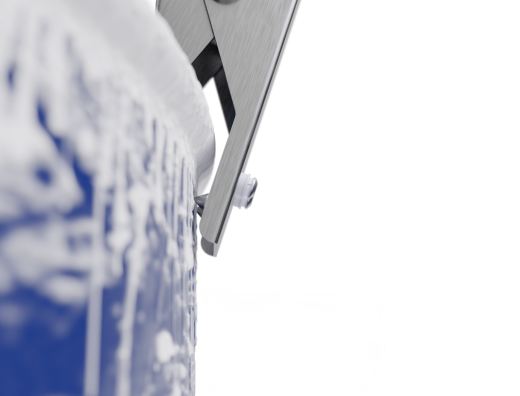

In the case of painted metal drums, or drums covered in product deposits (e.g., resins, coatings), it is important for the earthing clamp to penetrate these layers through to the base metal of the drum to enable static charges to pass from the drum to earth. This issue is referenced in IEC 60079-32-1:1:

3.4 The establishment and monitoring of earthing systems (from IEC TS 60079-32-1).

“Pressure-type clamps should have sufficient pressure to penetrate any protective coating, rust, or spilled material to ensure contact with the base metal with an interface resistance of less than 10 Ω.”

Hazardous area classification

It is important to know what the hazardous area classification of the location is prior to specifying a static control solution. Due to their portability, metal drums, and Ex IBCs can be situated anywhere in the workplace. As active monitoring systems require Ex certification (for installation and use in Ex areas), Newson Gale has developed a range of active monitoring solutions that can cater for variations in zoning, the number of objects that require earthing, and the flexible location of associated apparatus like power supplies. In any event, all Newson Gale active monitoring systems utilise Intrinsically Safe (IS) circuits with equipment protection level ‘Ga’ which is suitable for use in a Zone 0 atmosphere or lower. This means the earthing clamp can be attached to points on the drum or Ex IBC if there would be some doubt as to the boundary between a Zone 0 and Zone 1 atmosphere.