Sources of electrostatic charge accumulation on vacuum trucks

Vacuum trucks and bulk chemical road tankers transferring flammable products require static earthing protection to mitigate the build-up of static electricity on the truck and equipment, like hoses, that are connected to the truck. If static electricity is allowed to accumulate, it will look to discharge at the earliest opportunity.

The factor that contributes to an electrostatic spark discharge in truck vacuuming operations is the accumulation of static charges on some parts of the transfer system. Due to the movement of charged material from the source location to the collection tank, electrostatic charges can accumulate on the lance, hose, hose connections, components within the tank and the chassis of the truck itself.

In order to mitigate against a static spark discharge into an Ex atmosphere during operations the truck and its associated equipment and components should be bonded and earthed.

Earthing of vacuum trucks

Vacuum truck operations will normally be conducted in remote locations in refineries and chemical facilities where “designated” earthing points may not be tested on a regular basis, are not accessible, or even do not exist.

Of the many recommendations outlined in American Petroleum Institute (API) 2219 “Safe Operation of Vacuum Trucks”, the most relevant instruction is to fully earth the truck by connecting it to “a designated, proven ground source” before commencing with transfer operations. The “ground source” describes an object with a low resistance connection to the general mass of the earth.

The standard also states the importance of confirming that the connection resistance between the truck and the designated earthing point is less than 10 ohms and that this resistance should be verified with the use of an ohmmeter (or a multi-meter).

Guidance and standards

Wherever possible, Newson Gale adopts guidance on electrostatic hazards by standards publishing institutions that can help define the parameters for effective earthing and bonding in Ex atmospheres. In IEC 60079-32-1 “Explosive atmospheres – electrostatic hazards, guidance”, the guidance with respect to the loading (or unloading) of vacuum trucks states the following:

8.8.4 Vacuum trucks

“Vacuum trucks should be connected to a designated site earth before commencing any operations. In areas where site earths are not present, i.e. where portable earthing rods are required, or there is doubt regarding the quality of site earths, the resistance to earth should be verified prior to any operation. When the truck is connected to a verified earth, the connection resistance between the truck and verified earth should not exceed 10 Ω for pure metallic connections or 1 MΩ for all other connections.

This requirement should be verified with a truck mounted earthing system or portable ohmmeter. The electrostatic suitability of the hoses used should also be verified in accordance with 7.7.3 or 9.3.3.”

The Earth-Rite® MGV

The Earth-Rite® MGV is a truck-mounted earthing system that determines if the “ground source” it is connected to has a low resistance connection to the general mass of the earth. It has a user-friendly operator interface which indicates when the truck has a connection to earth.

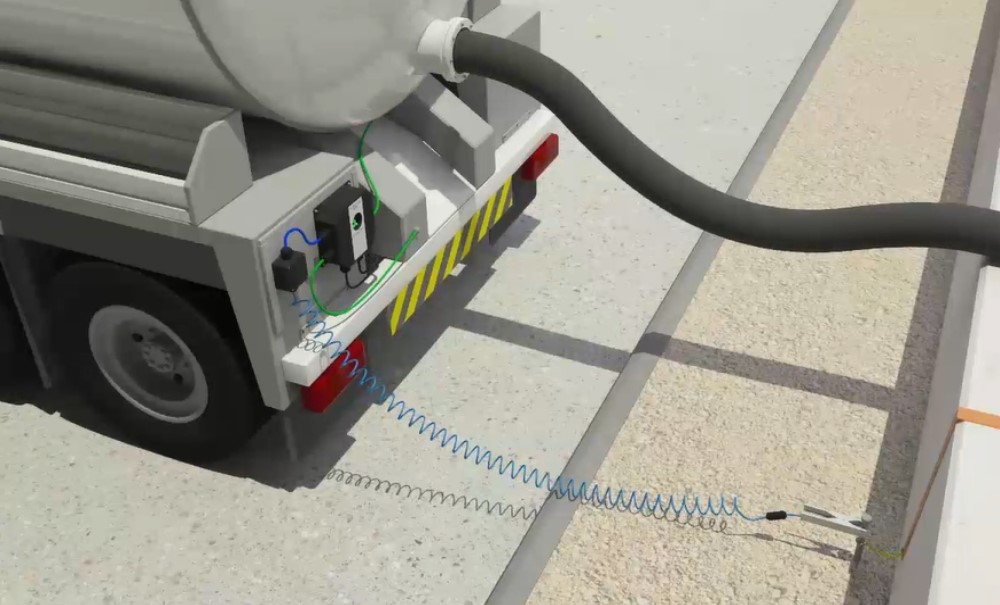

The earthing system can be connected with a static earthing clamp to either buried structural metal work or rods that are hammered into the ground. When the operator connects the clamp to the object believed to have a low resistance path to earth, the earthing system immediately verifies whether or not the contact resistance of the object to earth is sufficiently low enough to dissipate static charges. This function is referred to as “Static Ground Verification”.

Once this connection to earth is verified, the Earth-Rite® MGV continuously monitors the connection resistance of the truck to the verified earthing point for the duration of the transfer process; this is referred to as “Continuous Ground Loop Monitoring”. The connection resistance between the vacuum truck and the ground source must be maintained at 10 ohms or less for the duration of the transfer process. Both the Static Ground Verification and Continuous Ground Loop Monitoring checks need to be positive in order for the earth status indicators to change from red to green.

An additional form of safety redundancy can be introduced by interlocking the pump with the earthing system, so that if the truck loses its earth connection, the transfer process is shut down automatically, thereby cancelling out the generation of electrostatic charges.